Common Issues Faced in Copper Welding Processes and How to Overcome Them

Table of Contents

- Understanding the Unique Properties of Copper in Welding Applications

- Common Challenges in Copper Welding: Heat Management Issues

- Strategies for Minimizing Oxidation During Copper Welding

- Selecting the Right Filler Materials for Copper Welding Projects

- Techniques to Improve Arc Stability in Copper Welding Processes

- Regular Maintenance Tips to Enhance Copper Welding Equipment Performance

- FAQS

- Conclusion

- Related Posts

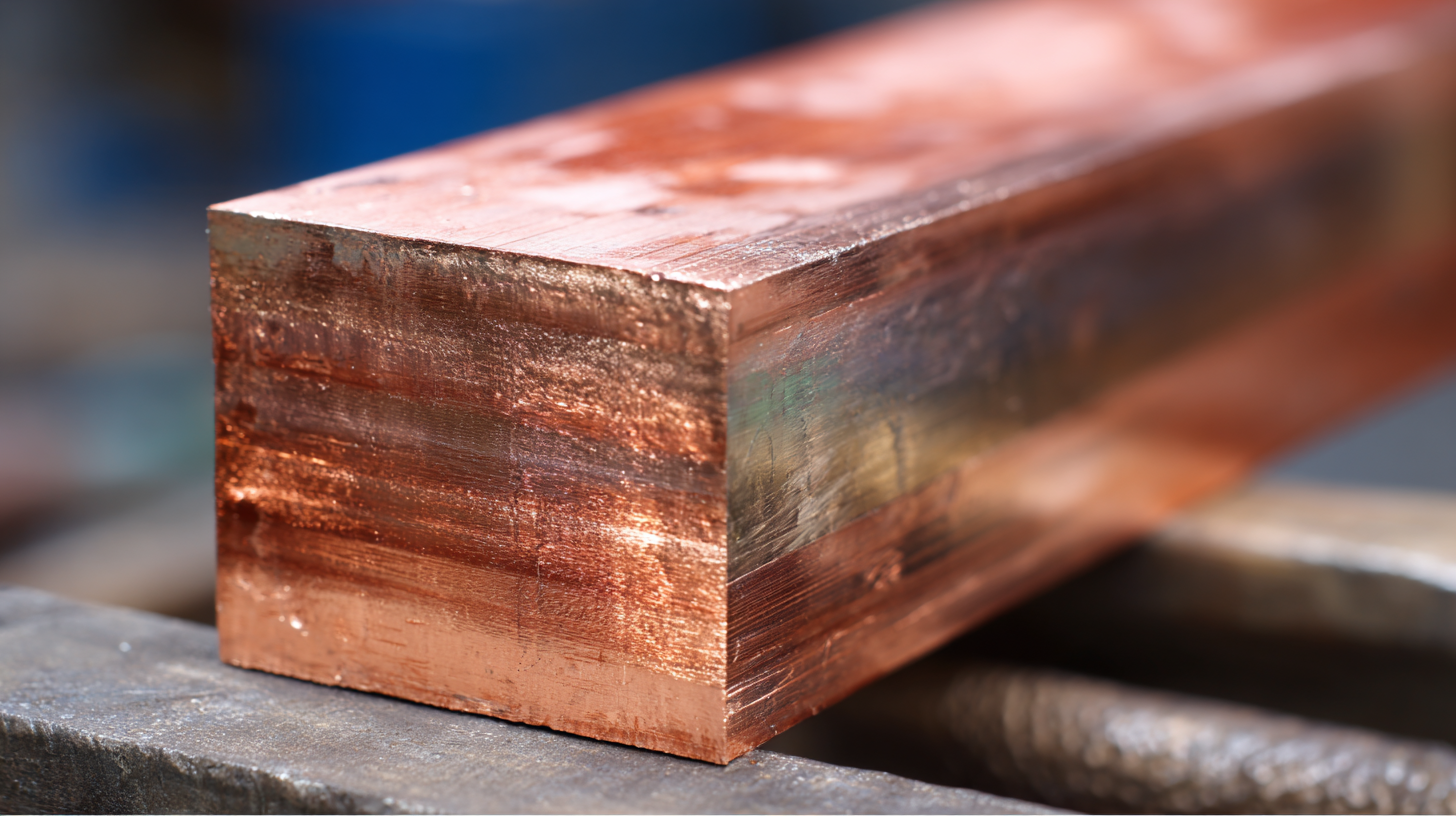

Copper welding plays a pretty vital role in lots of different industries, but let's be honest—it comes with its own set of tricky challenges. Here at Wenzhou Tianyu Electronic Co., Ltd., we've been in the game for over 22 years, making welding electrodes and consumables. Trust me, we’ve seen it all, so we know exactly what can go wrong when you're working with copper. Issues like electrode compatibility, uneven heat distribution, and oxidation can really mess with the quality of the welds, sometimes leading to weak joints or just not-so-great results. The good news? By pinpointing these common hiccups and applying some smart strategies, welders can step up their game, making stronger, more reliable welds. In this blog, I’ll walk you through the most typical problems folks face with copper welding and share some practical tips—drawing from our experience and the top-notch products we develop here at Wenzhou Tianyu Electronic. Hopefully, it’ll help you improve your welding skills and get better results every time.

Understanding the Unique Properties of Copper in Welding Applications

Copper’s a pretty amazing metal, mainly because it conducts heat and electricity so well. That’s actually why it’s a top pick for lots of welding jobs. But, honestly, working with copper isn’t always smooth sailing. For one, it heats up super fast, so if you're not careful, you might end up warping or distorting the piece. Plus, because it conducts heat so efficiently, you need to be extra mindful about making sure it heats evenly — otherwise, parts nearby could get overheated too.

Another thing to watch out for is oxidation. When you’re welding copper at high temperatures, it tends to form a layer of copper oxide, and that can really mess up the bond—making the joint weak and fragile. To tackle these issues, many welders use protective gas shields to keep oxygen out and prevent oxidation. They also pick filler materials designed specifically for copper to get the best results. Knowing these quirks of copper and having a game plan to deal with them makes all the difference. If you get it right, you’ll end up with strong, durable welds that work well and last a long time.

Common Challenges in Copper Welding: Heat Management Issues

When you're working with copper welding, one of the biggest hurdles you’ll face is managing the heat. Copper’s got super high thermal conductivity, which basically means it tends to spread out heat really quickly. So, if you’re not careful, the heat can just dissipate too fast, making it tough to get a solid weld. Overheating is another issue—it can cause warping or mess up the joint’s strength. That’s why keeping a close eye on heat input is such a big deal if you want good results with copper.

To keep things in check, try lowering the amperage on your welding machine—that way, you reduce the heat going in and lower the chances of overheating your copper. Also, shortening the arc length can help focus the heat right where you need it, which is pretty handy. And if you really want to get precise, using a heat sink — like a copper block — can soak up excess heat and give you more control over the temperature during welding.

Another trick that works wonders is preheating the copper parts before you start welding. It helps cut down thermal shock and spreads the heat more evenly, leading to a better quality weld overall. Get these heat management techniques down, and you’ll be surprised at how much easier it becomes to make strong, reliable copper welds.

Strategies for Minimizing Oxidation During Copper Welding

Copper welding is a pretty important part of a lot of industrial work, but let's be honest—it can be tricky, especially when it comes to oxidation. That pesky oxidation can weaken your welds and even cause them to fail way earlier than they should. So, it’s really key to have some good strategies up your sleeve to keep it at bay.

A good starting point? Keep your workspace super clean. Before you get started, make sure all the surfaces are free of dust, grease, or any oxidation layer. Giving the copper a scrub with a stainless-steel brush or wiping it down with a solvent can make a huge difference in the quality of your weld. And if you can, using shielding gas during welding helps protect the area from the air, which basically reduces the chances of oxidation happening.

Another thing to play around with is your welding settings. Turning down the heat a bit or moving a little faster can cut down on heat exposure, which in turn can help keep oxidation from forming. Don’t be afraid to tweak your machine’s settings—you’ll find that sweet spot that gives you solid welds and keeps oxidation in check. Overall, staying clean and paying attention to your technique really pays off—your copper welds will turn out way better, I promise.

Selecting the Right Filler Materials for Copper Welding Projects

When you're working with copper welding, picking the right filler materials is kinda a big deal if you want your welds to be solid and reliable. Copper’s a pretty special metal — it’s got high thermal and electrical conductivity, which honestly affects not just how you weld it, but also what filler you should use. Usually, the fillers for copper are made to match its unique properties, giving your weld strength and durability. It’s really important to choose a filler that expands at a similar rate to copper and fits what you’re planning to do with it.

By 2024, there are loads of options out there when it comes to welding rods for copper projects. The best bet is to go for rods made specifically for copper or copper alloys because they tend to give you better weld quality. Keep an eye on things like melting point, tensile strength, and how bendable (or ductile) the filler is — these will make a difference. An ideal filler should go on smoothly, resist oxidation while you’re welding, and help avoid common problems like porosity or cracking. If you pick the right filler and use it right, it can really boost your chances of getting a strong, lasting weld. Trust me, it’s worth the extra thought — you want your joints to hold up, right?

Common Issues Faced in Copper Welding Processes and How to Overcome Them - Selecting the Right Filler Materials for Copper Welding Projects

| Issue | Description | Suggested Filler Material | Solution |

|---|---|---|---|

| Porosity | Presence of tiny holes in the weld due to trapped gases. | Silicon Bronze | Ensure proper cleaning of the base metal and control the welding parameters. |

| Cracking | Fractures that develop in the weld bead or heat-affected zone. | Copper-Silicon Alloy | Keep the welding area free from stresses and ensure proper preheating. |

| Lack of Fusion | Inadequate bonding between the filler material and the base metal. | Nickel-Based Filler | Increase heat input and ensure proper joint fitting. |

| Color Mismatch | Differences in color between base metal and filler material after welding. | Copper Phosphorus Alloy | Choose fillers that closely match the base material in appearance. |

| Overheating | Excessive heat causes distortion or melting of the base material. | Aluminum Bronze | Control the heat input and use a suitable heat sink if necessary. |

Techniques to Improve Arc Stability in Copper Welding Processes

When you're working with copper welding, keeping the arc steady is pretty much key to getting good, high-quality welds. One of the most common headaches welders run into is the arc flickering or fluctuating—it can mess up the penetration and make your bead look uneven. To avoid that, there are a few tricks you can try to keep that arc more stable during your welds.

For starters, make sure your equipment is set up just right. Check the welder’s settings based on the thickness and type of copper you're working with. Tweaking the voltage and wire feed speed to match your specific job can really help keep things smooth. Using the right shielding gas mix also makes a difference; it can protect your weld pool and help create a more consistent arc.

Pro tip: Don't forget to maintain your torch and consumables regularly. Worn-out tips can cause issues, so inspecting and replacing them when needed can boost your efficiency and keep the arc steadier. And speaking of techniques, using push or pull motions when feeding the filler rod can help maintain an even, stable arc—making it easier to nail that perfect weld on copper.

Regular Maintenance Tips to Enhance Copper Welding Equipment Performance

When it comes to boosting the performance of your copper welding equipment, regular maintenance really makes a big difference. For starters, it’s a smart move to routinely check and clean those welding tips and nozzles. Since copper welding gets pretty hot, it’s common for oxidation and gunk to build up on them. Keeping these parts clean not only helps you get better welds but also extends the life of your tools.

Oh, and don’t forget about the cooling system—making sure it’s working properly can save you a headache by preventing overheating, which is a major buzzkill for efficiency. Setting up a regular schedule to check coolant levels and swap out filters is worth it. Plus, keeping an eye on the electrical wiring for any signs of wear or damage can save you from unexpected breakdowns—no one wants those surprises during a job.

If you build these little habits into your routine, you’ll find that copper welding becomes way smoother, more reliable, and way less stressful overall.

Common Issues Faced in Copper Welding Processes

This chart illustrates the common issues faced during copper welding processes along with their frequency of occurrence. Proper maintenance can significantly reduce these issues.

FAQS

: Copper is highly conductive, both thermally and electrically, which presents challenges such as rapid heat absorption that can lead to warping, and oxidation at high temperatures that can hinder strong bonds.

Welders can use a protective gas shield to prevent oxidation or select appropriate filler materials designed specifically for copper welding.

The right filler material complements copper's unique properties, ensuring strength and resilience in the weld while minimizing issues like oxidation, porosity, or cracking.

Key characteristics include the filler material's melting point, tensile strength, ductility, and compatibility with the base material’s thermal expansion.

Regular maintenance, such as inspecting and cleaning welding tips and nozzles, monitoring cooling systems, and checking electrical connections, helps prevent overheating and prolongs equipment lifespan.

Recommended tasks include routine inspections, cleaning of components to remove oxidation and contaminants, checking coolant levels, and replacing filters to ensure optimal performance.

Poor maintenance can lead to overheating, reduced welding efficiency, increased downtime, and ultimately poorer weld quality.

Oxidation can create a copper oxide layer that weakens the bond between the weld materials, leading to weak joints and reduced overall joint integrity.

Welding rods specifically designed for copper or copper alloys are best, as they enhance weld performance and reduce issues associated with high conductivity.

Proper cooling system function prevents overheating, a significant issue that can compromise welding quality and efficiency.

Conclusion

Copper welding can be pretty tricky sometimes because of the unique properties of the metal. It really demands some specialized techniques to get good results. One of the main issues folks run into is heat control — if you don’t manage it well, you might end up with warping or even burn-through. To avoid oxidation, it’s usually a good idea to use shielding gases or keep the weld area protected from air exposure. Choosing the right filler material is also super important to make sure the weld’s strong and compatible.

Getting a stable arc is another big deal because a consistent arc makes a huge difference in the overall quality of your weld. Also, don’t forget that maintaining your welding equipment regularly can really help you achieve better results. Here at Wenzhou Tianyu Electronic Co., Ltd., with over 20 years of experience in welding electrodes and consumables, we’re all about helping professionals tackle these common copper-welding challenges — so you can finish your projects with top-notch quality every time.

Related Posts

-

Unmatched Quality Best Cast Iron Welding Rods from China's Leading Manufacturer for Global Export

-

Unmatched Quality of Best Aluminum Welding Electrode from China to the World

-

Future Innovations in Welding: The Rise of Best Welding Cast Aluminum by 2025

-

15 Best Tips for Choosing the Best Flux Core Mig Wire for Your Business

-

How to Identify Top Manufacturers for the Best Copper Brass Products Globally

-

Future Trends in Best Welding Rod Size for Global Buyers How to Navigate the 2025 Market Analysis

Blog Tags: