Maximizing Your Welding Efficiency: The Advantages of Using Tig Welding Filler Rods

Table of Contents

- Understanding TIG Welding and Its Applications

- Top 5 Benefits of Using TIG Welding Filler Rods

- Why TIG Welding Filler Rods Enhance Metal Fusion Quality

- How TIG Filler Rods Improve Overall Welding Efficiency

- The Role of Alloy Composition in TIG Filler Rod Performance

- Tips for Selecting the Right TIG Welding Filler Rods for Your Projects

- Enhance Your Welding Projects with ERNiFeCr-1 Nickel Alloy Welding Wire: The Ultimate Nickel Tig Wire Filler Metal Guide

- FAQS

- Conclusion

- Related Posts

In the ever-changing world of welding, getting the right mix of efficiency and quality is honestly what makes a real difference in your welds. Did you hear? The American Welding Society estimates that by 2025, the welding market could hit a whopping $20 billion—shows just how important advanced techniques and quality materials are these days. Speaking of materials, Tig Welding Filler Rods are pretty popular because they offer such precision and versatility. They allow welders to make clean, strong joints with barely any spatter — pretty impressive, right? Wenzhou Tianyu Electronic Co., Ltd., started back in 2000, and they’ve been at it ever since, making welding electrodes and consumables. They’ve got a solid range now, including stainless steel and carbon steel electrodes. If you really want to step up your welding game, using top-quality Tig Welding Filler Rods can boost your efficiency and help your projects turn out better. Plus, it’s a small way to support the industry’s growth overall.

Understanding TIG Welding and Its Applications

So, if you’re into welding, you’ve probably heard of TIG welding—also known as Tungsten Inert Gas welding. It’s pretty awesome because it’s super precise and works well with thin materials or those tricky, detailed designs you might have. Basically, it uses a non-consumable tungsten electrode to create the weld, and if you need to add filler metal, you do it manually, which gives you a lot of control over how the weld turns out. That’s why TIG is the go-to choice when you’re working on stuff like aerospace parts, car projects, or even metallic art, where quality and accuracy really matter.

When you're choosing filler rods, just keep in mind the compatibility with your base material. Picking the right filler makes a huge difference—if you’re working with stainless steel, for example, ER308 rods are usually your best bet because they weld nicely with stainless. It’s all about matching the materials to get a solid, neat weld.

And don’t forget, getting your settings right on your TIG welder is super important. Adjust the amperage based on how thick the metal is—if you go too high, you might burn through. A little tip: practice on some scrap pieces first. It’s well worth it because you’ll get a feel for your equipment and get better at controlling your welds before jumping into your actual project. Trust me, a little prep goes a long way in making your welds cleaner and more professional-looking.

Top 5 Benefits of Using TIG Welding Filler Rods

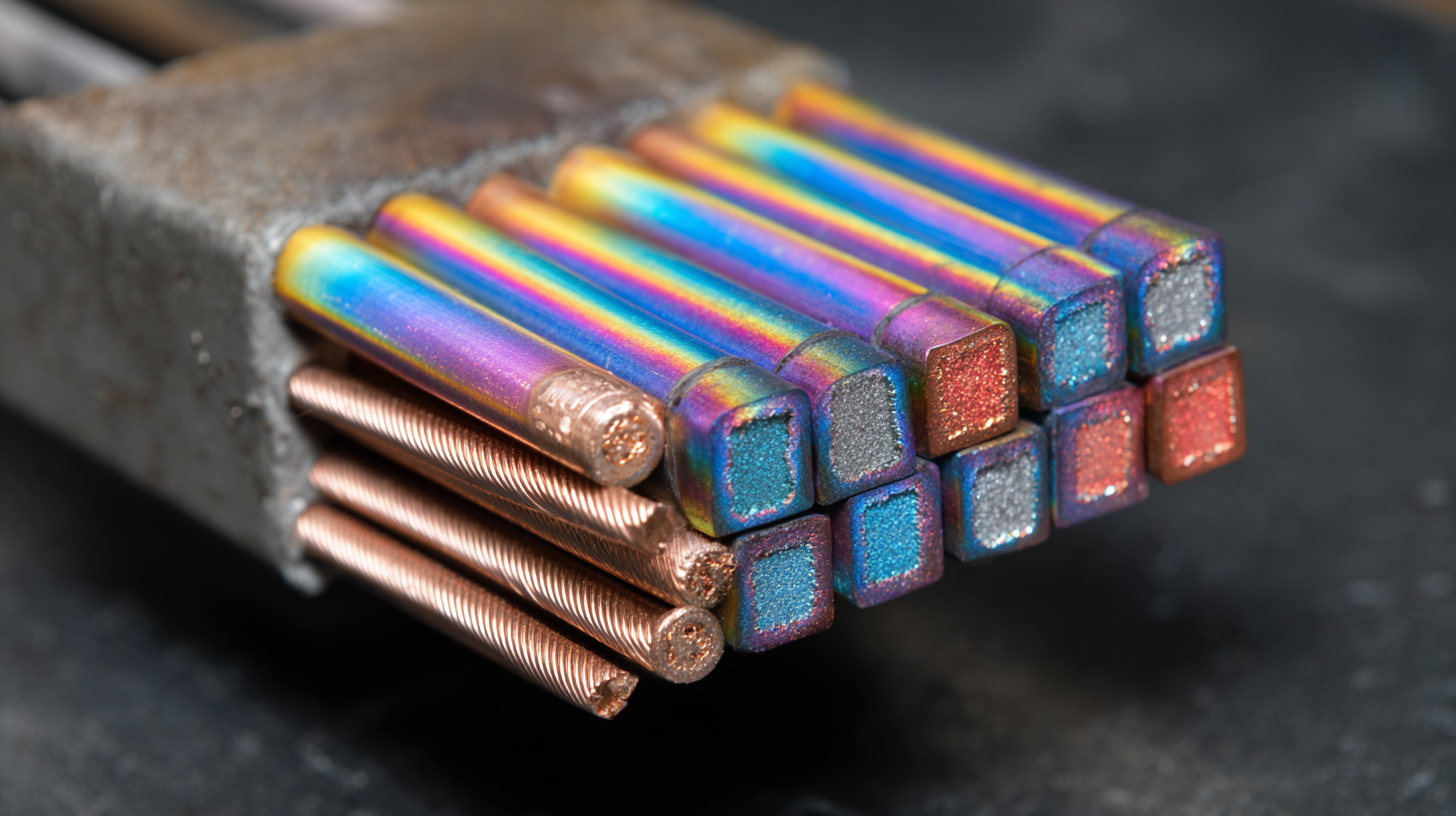

TIG welding, also known as Tungsten Inert Gas welding, is pretty well-loved for its precision and versatility. That's probably why it’s such a go-to choice across so many industries. One thing that really amps up the quality of TIG welding is using filler rods. So, I thought I’d share the top five perks of adding filler rods to your welding projects.

TIG welding, also known as Tungsten Inert Gas welding, is pretty well-loved for its precision and versatility. That's probably why it’s such a go-to choice across so many industries. One thing that really amps up the quality of TIG welding is using filler rods. So, I thought I’d share the top five perks of adding filler rods to your welding projects.

First off, filler rods help create stronger, more durable welds. When you pick the right filler material, it boosts the mechanical strength of the joint — making it not just solid but also resistant to stress and fatigue. That’s super important if you’re working on something where structural integrity really matters.

Plus, using filler rods gives you better control over the weld pool, which is a game-changer. This control helps you achieve a nice, smooth, professional-looking finish. A little tip: try to match your filler rod with the base metal. That way, you’ll improve compatibility and cut down on issues like corrosion or cracking.

And lastly, filler rods can actually make your welding process more efficient. They let you fill joints and connections faster, so you can get jobs done a lot quicker. Just a heads-up — choosing the right diameter of filler rod based on the thickness of what you’re welding really helps increase the deposition rate and cuts down on the overall time you spend at it.

Why TIG Welding Filler Rods Enhance Metal Fusion Quality

So, you know TIG welding—also called Tungsten Inert Gas welding—is pretty much the go-to for really high-quality welds. And honestly, the filler rods you choose play a big role in making those welds stand out. These rods are specially made to work perfectly with the shielding gas used during the process. Their consistent makeup helps them fuse seamlessly with the metal you're working on, which means stronger, more durable joints. Plus, having the right filler material kinda helps keep things clean and neat—no messy impurities or uneven spots, and the final weld just looks better overall.

On top of that, picking the right filler rod gives you more control over the weld pool. As a welder, you can tweak things like heat and how much filler you add, depending on the type of metal and how thick it is. That kind of flexibility makes a huge difference—your welds are both stronger and less prone to issues like porosity or cracking. When you use the right TIG filler rods, you're basically setting yourself up for a weld that lasts longer and looks cleaner. They’re really an essential part of any serious welding job.

Maximizing Your Welding Efficiency: The Advantages of Using Tig Welding Filler Rods - Why TIG Welding Filler Rods Enhance Metal Fusion Quality

| Filler Rod Material | Diameter (mm) | Typical Application | Heat Treatment | Recommended Amperage |

|---|---|---|---|---|

| ER4047 | 1.6 | Aluminum welding | Yes | 60-90 A |

| ER308L | 1.2 | Stainless steel welding | Yes | 70-110 A |

| ER70S-6 | 1.0 | Mild steel welding | No | 80-120 A |

| ER2319 | 2.4 | Aluminum-lithium alloys | Yes | 90-130 A |

How TIG Filler Rods Improve Overall Welding Efficiency

You know, TIG (Tungsten Inert Gas) welding has really become a go-to method for a lot of manufacturers these days, mainly because of its precision and how versatile it is. One thing that really makes a difference in how efficient the whole process is? Using the right TIG filler rods. I came across a report from the American Welding Society that mentioned how choosing the proper filler materials can actually boost joint strength and cut down on defects — we're talking about up to a 30% jump in productivity! That’s super important especially in fields like aerospace and auto manufacturing, where the quality of each weld has to be top-notch.

Plus, these filler rods help create a cleaner, more controlled weld pool, which means better control over how deep the weld goes and the shape of the bead. There’s even a study in the International Journal of Advanced Manufacturing Technology that says high-quality filler rods can improve heat input and cut down distortion in welds by about 25%. This kind of control speeds things up and also cuts down on rework — saving time, money, and a lot of headaches. Basically, picking the right TIG filler rods lets welders get great results, work more efficiently, and make sure everything meets those tight industry standards for quality and safety.

The Role of Alloy Composition in TIG Filler Rod Performance

When you're diving into welding, especially with TIG, picking the right filler rod really makes a difference. It’s a key factor in how efficient and strong your welds turn out. You see, the performance of those TIG filler rods heavily depends on what they’re made of. For example, if you look at ER5356 rods, the amount of manganese in them can actually impact how strong and durable the welded aluminum joints become. That’s why choosing the proper filler material is so important — it helps you get the right mix of strength and resistance to corrosion, especially when you're working with dissimilar metals or in really tough environments.

Lately, some studies have looked into how different TIG filler rods, like ER4043 and ER5356, affect the final weld. Turns out, the alloy makeup has a big influence on the weld’s microstructure and overall mechanical properties, such as how much tension it can handle or how much it can stretch before breaking. Plus, the way the filler interacts with the base metals can change how resistant the weld is to corrosion. So, it’s pretty clear that understanding how different filler rod formulas work can really help welders improve their process and end results. At the end of the day, it's all about making sure your welds are not just good-looking but also durable enough to last long-term.

Maximizing Your Welding Efficiency: The Advantages of Using TIG Welding Filler Rods

Tips for Selecting the Right TIG Welding Filler Rods for Your Projects

When you're picking out the right TIG welding filler rods for your projects, it's really important to understand what materials you'll be working with. Different alloys need different fillers to get that perfect fusion and strength. For example, if you're welding stainless steel, you'll want to go for rods like ER308 or ER316 that match the metal you're working with. On the other hand, if you're dealing with aluminum, options like ER4047 or ER5356 are usually the go-to—they’re designed to give you a solid bond and a nice finish.

Also, don’t forget to consider the diameter of the filler rod. A thicker rod might be better if you're working on something that needs to withstand high temps or extra reinforcement. But if you're doing more detailed, precise work, thinner rods are usually the way to go—they give you better control. Plus, think about the overall project—things like joint design and the welding position can influence your choice. Picking the right filler rod like this not only boosts the quality of your welds but can also save you time and materials by cutting down on rework and waste. It’s all about finding that sweet spot to make your job smoother and more efficient.

Enhance Your Welding Projects with ERNiFeCr-1 Nickel Alloy Welding Wire: The Ultimate Nickel Tig Wire Filler Metal Guide

When it comes to enhancing your welding projects, the choice of filler metal can make all the difference. ERNiFeCr-1 nickel alloy welding wire, also known as Alloy 825, stands out as a premier option for welders tackling challenging tasks. Composed of nickel, iron, and chromium, this versatile wire offers excellent corrosion resistance and mechanical properties, making it ideal for industries ranging from chemical processing to nuclear applications.

One of the key benefits of using ERNiFeCr-1 is its ability to perform well in environments that subject materials to extreme conditions. Its unique composition allows for effective bonding to a variety of base metals, providing weld integrity even in the face of stress and fatigue. Whether you're working on piping systems, pressure vessels, or any project that requires reliability, this nickel TIG wire filler metal ensures that your welds will not only be strong but also resistant to the corrosive elements often found in critical applications.

By incorporating ERNiFeCr-1 into your projects, you’re investing in a product that delivers superior performance and longevity. It's not just another filler metal; it’s a solution designed for those who refuse to compromise on quality, enabling you to elevate your craftsmanship to new heights. Whether you are a seasoned professional or an enthusiast, this welding wire is sure to enhance your capabilities and the outcomes of your welding endeavors.

FAQS

: TIG welding, or Tungsten Inert Gas welding, is a precise welding process ideal for thin materials and intricate designs, using a non-consumable tungsten electrode to produce the weld.

Using compatible filler rods ensures a strong and cohesive weld, improving the mechanical properties of the weld and resulting in durable joints that resist stress and fatigue.

The benefits of incorporating TIG welding filler rods include stronger welds, better control over the weld pool for a smoother appearance, and increased productivity by allowing faster filling of joints.

Select filler rods based on the base material you are working with; for example, use ER308 or ER316 for stainless steel and ER4047 or ER5356 for aluminum.

The diameter of the filler rod affects the welding process; thicker rods are suitable for high-temperature applications requiring reinforcement, while thinner rods are ideal for detailed work requiring precision.

To prevent burn-through, adjust the amperage on your TIG welder according to the thickness of the material you’re welding, and consider practicing on scrap materials to refine your technique.

Improve efficiency by selecting the appropriate diameter of filler rod based on material thickness, optimizing compatibility, and reducing waste and rework through careful material selection.

Practicing on scrap materials helps you better understand your welder's capabilities, refine your technique, and improve overall welding efficiency before starting on your main project.

TIG welding is particularly suitable for industries such as aerospace, automotive, and art metalwork, where precision and quality are essential.

Consider the overall project requirements, including joint design and welding position, to select the right filler rod that enhances weld quality and efficiency.

Conclusion

When you’re into welding, getting a good handle on TIG welding and knowing when and how to use it can really make a difference. One thing that often gets overlooked but is super important is choosing the right TIG Welding Filler Rods. These little guys do more than just fill in gaps — they actually boost the overall quality of your welds and can make your work way more efficient. Using the correct filler rod means less contamination, better resistance to rust and corrosion, and stronger, more reliable joints. Honestly, picking the right rod can really take your welding projects to the next level.

And here’s a little detail that matters — the alloy composition of the TIG Filler Rods. It impacts things like melting point and how sturdy the weld will be. So, making sure you select the right type for your specific job is key to getting the best results. It just smooths out the whole process and helps you work more effectively. At Wenzhou Tianyu Electronic Co., Ltd., we’re all about providing top-quality welding consumables that help pros like you hit your goals with confidence.

Related Posts

-

Evaluating the Advantages of Tungsten Welding vs. Alternative Welding Methods for Global Manufacturing

-

Exploring the Advantages and Applications of the Top Welding Electrode Types

-

The Ultimate Guide to Sourcing High Quality Aluminum Sticks for Global Markets

-

Future Innovations in Welding: The Rise of Best Welding Cast Aluminum by 2025

-

Common Issues Faced in Copper Welding Processes and How to Overcome Them

-

Mastering Hard Facing Techniques with the Best Hard Facing Welding Rods for Superior Durability

Blog Tags: