Ultimate Checklist to Choose the Best Tig Wire for Your Welding Projects

Table of Contents

- Common Issues Associated with Different Types of Tig Wire

- Factors Affecting the Performance of Tig Wire in Welding

- Comparative Analysis of Tig Wire Types for Application-Specific Needs

- How to Identify and Troubleshoot Welding Problems with Tig Wire

- Choosing the Right Tig Wire: Avoiding Common Pitfalls

- Maintenance Tips for Ensuring Optimal Performance of Tig Wire

- Unlocking Superior Welds: Insights from Recent Market Trends on AWS ER308LSi Stainless Steel Welding Solutions

- FAQS

- Conclusion

- Related Posts

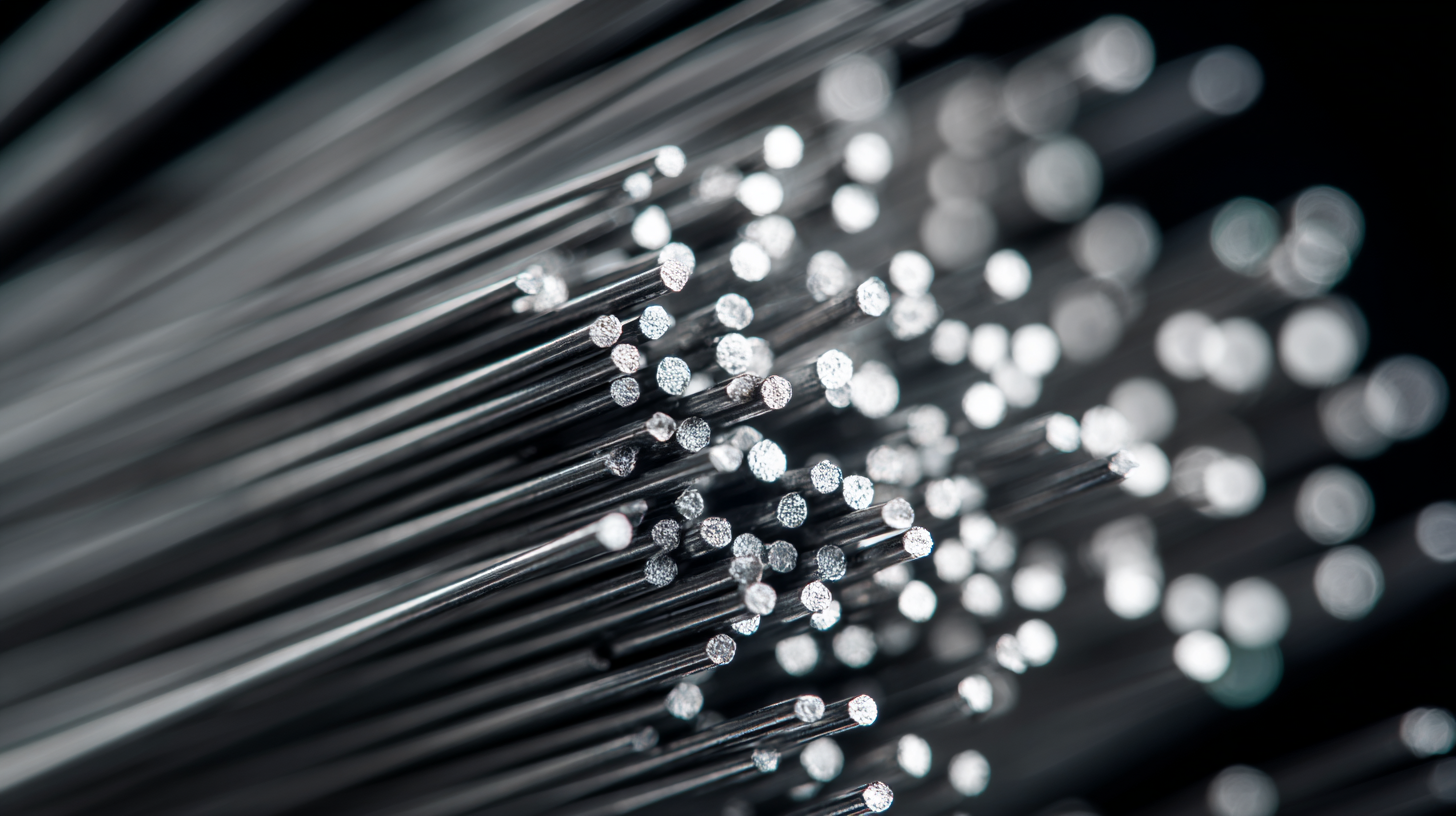

When you're aiming for really good welds, picking the right TIG wire is super important—trust me, it can make or break your project. Here at Wenzhou Tianyu Electronic Co., Ltd., we've been around since 2000, and over all these years, we've carved out a solid reputation for providing top-quality welding electrodes and consumables—think stainless steel, carbon steel, low alloy options, and more. With our years of industry know-how, we’re in a pretty good spot to help you figure out exactly what you need when it comes to choosing your TIG wire. Whether you're working on delicate, detailed fabrications or heavy-duty structural jobs, understanding the different types and specs of TIG wire can really level up your welding game. So, in this handy checklist, we’ll break down the main factors to think about so you can make a confident choice that lines up perfectly with what you’re aiming for in your welding projects.

When you're aiming for really good welds, picking the right TIG wire is super important—trust me, it can make or break your project. Here at Wenzhou Tianyu Electronic Co., Ltd., we've been around since 2000, and over all these years, we've carved out a solid reputation for providing top-quality welding electrodes and consumables—think stainless steel, carbon steel, low alloy options, and more. With our years of industry know-how, we’re in a pretty good spot to help you figure out exactly what you need when it comes to choosing your TIG wire. Whether you're working on delicate, detailed fabrications or heavy-duty structural jobs, understanding the different types and specs of TIG wire can really level up your welding game. So, in this handy checklist, we’ll break down the main factors to think about so you can make a confident choice that lines up perfectly with what you’re aiming for in your welding projects.

Common Issues Associated with Different Types of Tig Wire

When you're working with TIG welding, choosing the right wire can really make a difference in how your project turns out. There are different types of TIG wire, each designed for specific materials, and using the wrong one can lead to some pretty common problems. For example, ER70S-2 is known to be pretty versatile when welding mild steel, but if you try to use it on stainless steel, you might end up with contamination or poor fusion because of unwanted elements in the wire.

And if you're working with aluminum, wires like ER4047 can be a bit tricky—if not handled properly, you might get porosity in your welds. That usually happens if the aluminum isn’t cleaned well beforehand or if you’re not using the right shielding gas. When it comes to nickel alloys, using the wrong filler rod can cause cracking or weak joints, which is the last thing you want. So, getting to know the properties of each wire and making sure they match what you're welding on is super important. Being aware of these issues upfront can save you a lot of time and headaches down the line—trust me, it’s worth it to do your homework before starting up.

Ultimate Checklist to Choose the Best Tig Wire for Your Welding Projects - Common Issues Associated with Different Types of Tig Wire

| Tig Wire Type | Material | Diameter (mm) | Common Uses | Common Issues |

|---|---|---|---|---|

| ER70S-2 | Mild Steel | 0.8 | General Steel Fabrication | Porosity and Incomplete Fusion |

| ER308L | Stainless Steel | 1.0 | Welding of 18-8 Stainless Steel | Cracking and Poor Cleanliness |

| ER4047 | Aluminum | 1.2 | Automotive and Marine Applications | Poor Ductility and High Shrinkage |

| ER5356 | Aluminum Magnesium Alloy | 1.6 | Marine Applications | Weld Cracking and Corrosion |

Factors Affecting the Performance of Tig Wire in Welding

When you're choosing TIG wire for your welding projects, it’s pretty important to understand what factors can affect how well it performs. For example, the material composition really matters — aluminum wires, stainless steel wires, they all have their own unique properties and are suited for different jobs. Picking the right alloy isn’t just about ticking a box; it actually makes a big difference in how strong, ductile, and resistant to rust your welds will be, depending on what you're working on.

Here’s a little tip: always take a look at the mill certificates that come with the wire. That way, you can double-check that the chemical makeup matches what your project calls for. It’s a simple step that can save you from ending up with a weld that’s weak or unreliable.

Another thing to keep in mind is the wire diameter. This might sound technical, but it really affects how much heat you’re putting in and how much control you have over the weld pool. You’ll find that thinner wires are better for detailed or delicate work, while thicker wires can provide the strength you need for heavier, tougher jobs.

And here’s a little pro tip: don’t be afraid to practice with different diameters. Trying out a few in your practice sessions is a great way to see what feels best for your style and the kind of work you're doing. Honestly, a bit of hands-on experimenting can seriously boost your confidence and make your welding way more efficient.

Comparative Analysis of Tig Wire Types for Application-Specific Needs

When you're trying to pick the best TIG welding wire for your projects, it’s super important to understand the different types and what they’re actually good for. The American Welding Society (AWS) sorts these electrodes and wires based on their composition. For example, ER70S-2 and ER308L are two of the most commonly used options out there.

ER70S-2 is great for carbon steel—it's known for stable arcs and being really user-friendly, so a lot of welders rely on it for general fabrication work. On the flip side, ER308L is the go-to choice when working with stainless steel since it has awesome corrosion resistance and can hold up well even at higher temperatures. A report from the Welding Research Institute really emphasizes how choosing the right wire can boost weld quality by up to 30%, which is pretty significant.

Also, don’t forget to think about the wire diameter and filler metal details for each specific job. For example, a 0.030-inch wire tends to work well on thinner materials, while thicker stuff might need a 1/16-inch wire to get better penetration and strength. Industry data shows that using the wrong wire can cause weld defects, which often means more reworking—costing up to 40% more in some cases.

So, taking the time to compare different TIG wires based on what you’re actually welding can really make a difference—helping you get better results, save time, and stick to modern fabrication standards more easily.

How to Identify and Troubleshoot Welding Problems with Tig Wire

When you're working with TIG welding, troubleshooting common wire-related issues can really make a difference in the quality of your work. For example, if your arc keeps flickering or wandering all over the place, that’s usually a sign something’s off — maybe your tungsten electrode is contaminated or not the right size. It's a good idea to regularly check the tip of your tungsten and make sure it's sharpened properly. It helps keep the arc stable, which in turn results in cleaner, more consistent welds.

Another thing you might notice is that your bead doesn’t look quite right. If the weld bead is uneven or looks kinda ragged, it could be due to the filler metal not feeding properly. Sometimes, if the wire diameter isn’t the right fit for the project, feeding can get all wonky, leading to a weak or choppy weld. Also, don’t forget to keep an eye on the wire’s cleanliness and moisture content — both can mess with the weld quality if they’re not right.

By getting a good grasp on these common issues and knowing how to fix them, you’ll find your welding process flows a lot smoother, and your results just keep getting better. It’s all about understanding what’s happening under the hood, so to speak, and making small adjustments as needed.

Ultimate Checklist for Selecting the Best Tig Wire

Choosing the Right Tig Wire: Avoiding Common Pitfalls

When you're picking out the right TIG wire for your welding projects, it's really important to avoid some common mistakes that can end up messing up your results. First off, you gotta think about what the wire is actually made of. Different jobs need specific alloys—like stainless steel or low alloy—and it’s crucial to match that with the right filler material. That way, you get the best joint strength and won’t have to worry about rust or corrosion later on. As someone who's been in the game of making welding electrodes and consumables, Wenzhou Tianyu Electronic Co., Ltd. stresses how vital it is to really understand what your project needs before making a choice.

Also, don’t forget to check the wire’s diameter and make sure it’s compatible with your welding machine. Using the wrong size can mess with the heat input and even mess up your weld quality. And it’s worth thinking about who’s making the wire—going for a trusted brand like Wenzhou Tianyu means you’re more likely to get consistent, reliable results. If you keep these things in mind, you’ll be making smarter decisions that boost your welding results and help you avoid those frustrating mistakes that can really set you back.

Maintenance Tips for Ensuring Optimal Performance of Tig Wire

When you're working with TIG welding, taking good care of your wire is super important if you want everything to turn out right. Regularly checking your wire and storing it properly makes a big difference. I’ve read that if TIG wire isn’t stored well, it can soak up moisture and dirt, which messes up the weld quality. The American Welding Society even says that contaminants can cut the tensile strength of your weld by almost half—talk about a potential disaster! So, to keep things running smoothly, it’s best to keep your TIG wire in a dry, clean spot, like sealed containers that keep humidity out.

When you're working with TIG welding, taking good care of your wire is super important if you want everything to turn out right. Regularly checking your wire and storing it properly makes a big difference. I’ve read that if TIG wire isn’t stored well, it can soak up moisture and dirt, which messes up the weld quality. The American Welding Society even says that contaminants can cut the tensile strength of your weld by almost half—talk about a potential disaster! So, to keep things running smoothly, it’s best to keep your TIG wire in a dry, clean spot, like sealed containers that keep humidity out.

Another key thing is how you feed the wire during welding. The AWS points out that if the wire isn’t aligned correctly, you might get more spatter and an unstable arc. That not only makes for rougher looking welds but also wastes extra material. To avoid that, make sure the wire feeds straight into the torch and doesn’t have any kinks or bends—that really makes a difference. And don’t forget, giving your torch a quick clean now and then, and keeping an eye on the arc length, helps keep your welds solid and consistent. At the end of the day, a little extra attention pays off with stronger, more dependable welds.

Unlocking Superior Welds: Insights from Recent Market Trends on AWS ER308LSi Stainless Steel Welding Solutions

The recent trends in the market for AWS ER308LSi stainless steel welding solutions reveal the growing demand for high-performance welding materials. Stainless steel welding wire is celebrated for its exceptional cladding efficiency and versatility, enabling flawless execution in all-position welding. According to a report by the Global Institute of Welding Technologies, the global demand for stainless steel welding wire is projected to grow at a CAGR of 5.2% from 2023 to 2028, driven by its extensive applications across various industries.

Industries such as building construction, automotive manufacturing, and bridge engineering heavily rely on stainless steel welding wire for their projects. The impressive technical performance exhibited during welding operations ensures structural integrity and durability in challenging environments. A notable observation from the American Welding Society indicates that approximately 45% of all structural steel projects in the U.S. utilize stainless steel welding wire, highlighting its significance in ensuring safety and compliance with industry standards.

Furthermore, specific sectors including mining machinery and gas pressure-bearing equipment are increasingly turning to AWS ER308LSi welding solutions to enhance their operational efficiency. This welding wire not only accommodates high-strength applications but also provides excellent resistance against corrosion, making it ideal for power equipment and other critical infrastructure projects. As industry leaders continue to prioritize quality and reliability, the adoption of superior welding solutions will undoubtedly shape the future of stainless steel applications across multiple domains.

FAQS

: Using the wrong type of TIG wire can lead to problems like weld contamination and poor fusion, especially when attempting to weld materials that the wire is not designed for, such as using ER70S-2 on stainless steel.

Aluminum TIG wires, like ER4047, may face issues such as porosity if the aluminum is not properly cleaned before welding or if incorrect shielding gas is used.

The composition of the wire is crucial as different metals like aluminum and stainless steel have varying properties. Choosing the correct alloy ensures optimal strength, ductility, and corrosion resistance.

Always check the mill certificates of the TIG wire to ensure that the chemical composition matches your project needs for strong and reliable welds.

The diameter of the wire affects heat input and control over the weld pool. Thinner wire may be preferred for intricate designs, while thicker wire may provide the necessary strength for heavy-duty applications.

Flickering or wandering arcs can indicate problems, often caused by contaminated or incorrectly sized tungsten electrodes.

Poor bead appearance may result from inadequate filler metal feeding, which can occur if there is a mismatch between the wire diameter and the project requirements.

The wire's cleanliness is crucial because any dirt or moisture absorption can adversely affect the integrity of the weld, leading to weaker joints.

Regular inspection and proper sharpening of the tungsten electrode can help maintain an even arc, leading to cleaner welds.

Address issues such as arc stability, filler metal feeding inconsistencies, and maintain the cleanliness of the wire to ensure a smoother welding process and better results.

Conclusion

Hey there! If you've ever dived into the world of welding, you know how tricky it can be to pick the right Tig wire. That's why we put together the 'Ultimate Checklist to Pick the Best Tig Wire'—it’s packed with everything you need to know. We chat about the key things to think about for different types of Tig wire, including some common issues folks run into. Plus, we break down how different wires perform and help you compare options based on your specific needs. And if you're facing any welding headaches, we've got practical tips to troubleshoot and avoid the usual pitfalls when choosing your wire.

We also throw in some handy maintenance advice to keep your Tig wire working smoothly for longer. With over 22 years under our belt, Wenzhou Tianyu Electronic Co., Ltd. knows a thing or two about welding consumables. From high-quality electrodes to other welding supplies, we've got you covered—mainly because we believe that picking the right Tig wire is a big part of nailing those perfect welds. So, whether you're a beginner or a pro, this guide’s here to help you make smarter choices and get better results every time.

Related Posts

-

Exploring Opportunities for Ac Welding Rods at the Record Breaking 137th Canton Fair

-

Unlocking the Future of Best Welding Brass With Tig Strategies for Global Buyers in 2025

-

Unmatched Quality: China’s Premier Inconel 625 for Global Markets

-

Understanding Common Challenges with Best Smaw Electrode for Global Buyers

-

Common Issues Faced in Copper Welding Processes and How to Overcome Them

-

Evaluating the Performance of Nickel 55 Welding Rods: A Comparative Analysis with Alternative Alloys

Blog Tags: