Ultimate Guide to ER316L: Understanding Its Applications and Advantages in Industrial Welding

Table of Contents

- What is ER316L Welding Wire? Key Features and Specifications

- Top Applications of ER316L in Industrial Welding

- Advantages of Using ER316L Over Other Stainless Steel Alloys

- Impact of ER316L on Weld Quality and Durability

- Tips for Choosing the Right ER316L for Your Welding Projects

- Elevate Your Welding Projects with AWS ER316L Stainless Steel Welding Wire: A Comprehensive Guide to MIG and TIG Techniques

- FAQS

- Conclusion

- Related Posts

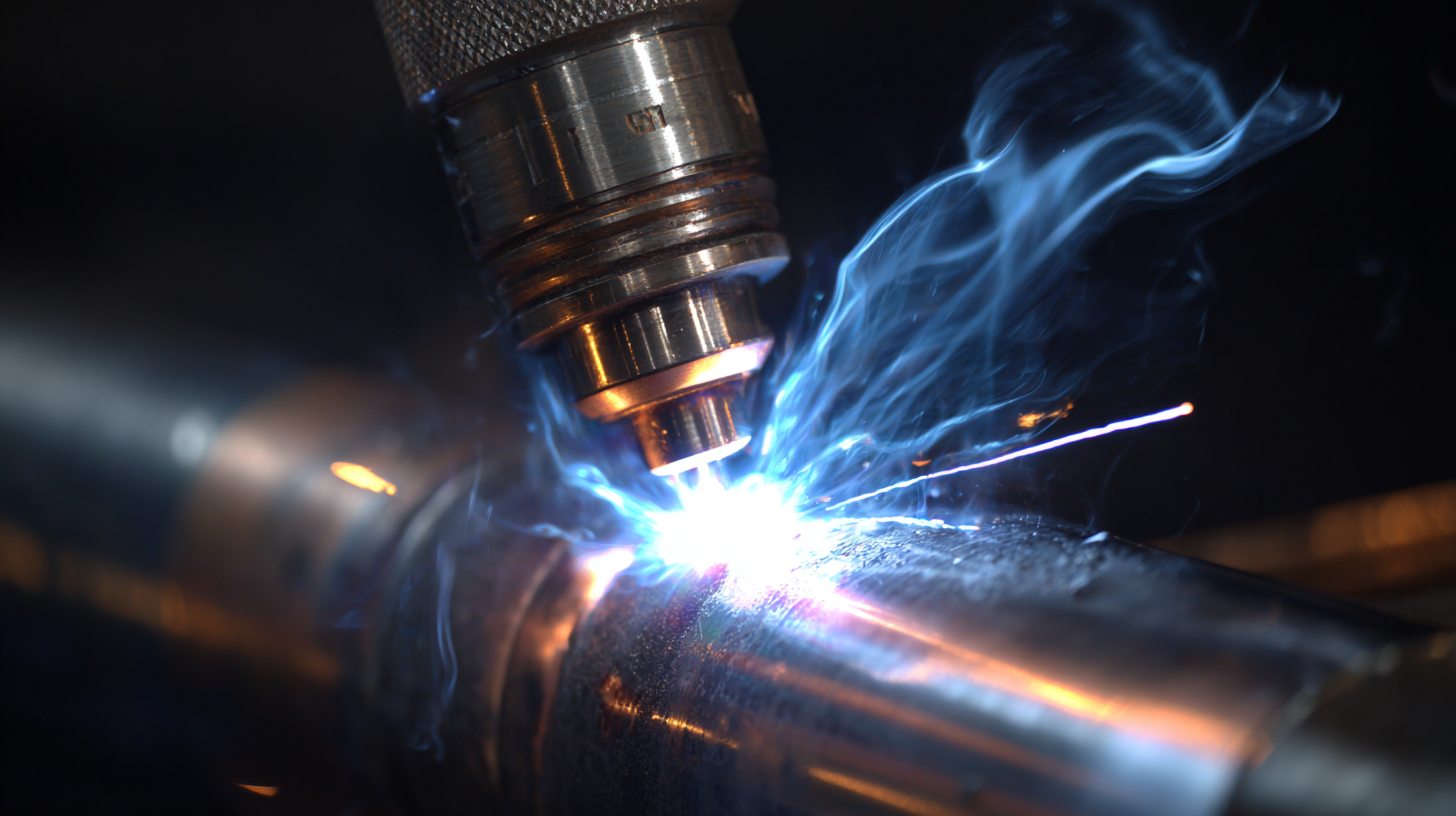

In the constantly changing world of industrial welding, picking the right materials is pretty much essential if you want everything to turn out just right and keep the structure solid. Out of all the welding rods out there, ER316L has really become a go-to choice, thanks to its special qualities and flexibility. It’s especially great in harsh, corrosive environments—think chemical plants, petrochemical setups, or even ships—where durability really matters.

Here at Wenzhou Tianyu Electronic Co., Ltd., with over 22 years of experience making top-notch welding electrodes and consumables, we’re confident in the perks and best uses of ER316L. Since we kicked things off in 2000, our goal has always been to provide welding solutions that can stand up to today’s tough manufacturing standards. In this guide, we’re going to explore why ER316L is such a solid pick—its specific uses and benefits—and hopefully, help you see why it should be at the top of your list for welding projects.

What is ER316L Welding Wire? Key Features and Specifications

ER316L welding wire is basically a low-carbon version of the regular 316 stainless steel. It's specially made for tough environments with higher temperatures. What’s cool about it? It’s got excellent corrosion resistance and high strength, making it a real go-to when you’re working in harsh settings—think marine stuff or industrial projects. This wire works well with both gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW), so it’s pretty versatile no matter what method you prefer.

A quick tip—make sure the base materials are super clean before you start welding. Any dirt or contaminants can mess with the quality of your welds. Also, preheating thicker sections can help prevent cracking, which is always a good idea.

One of the really nice features of ER316L is its resistance to pitting and crevice corrosion. Basically, it handles chloride-rich environments without giving you trouble. Plus, its low carbon content means less risk of carbide precipitation, so your welds stay tough and durable.

Another tip—stick to the recommended filler wire thickness for your project. Adjusting your welding settings properly can make the arc more stable and improve the overall strength of your welds. Bottom line, ER316L is a reliable choice for tough, lasting welds in challenging conditions.

ER316L Welding Wire Applications and Advantages

Top Applications of ER316L in Industrial Welding

ER316L is a pretty awesome stainless steel that folks often use in industrial welding, mainly because it’s really good at resisting corrosion and has solid mechanical properties. It’s especially handy in environments where chlorides are around, which is why it’s a go-to in many different fields. Industries like chemical processing, marine construction, and pharma rely on ER316L because it’s durable and dependable.

One of the really common uses of ER316L in the industrial world is making equipment for the chlor-alkali industry. That sector’s been growing quite a bit, and estimates suggest the market could hit around $1.15 billion by 2032. Using materials like ER316L can not only make sure that equipment lasts longer but also helps keep safety standards high.

**Quick tip:** When you’re picking out ER316L for your welding projects, it’s a good idea to think about the specific environment it’ll be working in. Also, using proper welding techniques and having some training under your belt can really make a difference in the quality of your welds and how well the final product performs. And don’t forget to double-check the material specs to make sure it’s the right fit for what you’re working on.

Advantages of Using ER316L Over Other Stainless Steel Alloys

When it comes to industrial welding, choosing the right filler material can really make a big difference in how long your welds last and how good they look. For example, ER316L is like a low-carbon version of the usual 316 stainless steel alloy. It’s known for being especially resistant to corrosion and less prone to that nasty intergranular corrosion, which is pretty awesome. Because of these qualities, ER316L is often the go-to choice in industries where quality really matters—think pharmaceuticals, food processing, and chemical production. There’s even a report from the Welding Research Council that says ER316L can handle harsh, corrosive environments way better than many other alloys, sometimes extending the service life by up to 50% in certain situations.

Pro tip: When you're picking your filler material, think about the kind of corrosion resistance you actually need. If your project involves chlorides—like in marine settings—ER316L is usually the better bet than other stainless steels.

What’s also pretty nice about ER316L is how easy it is to weld. Compared to its higher-carbon cousins, ER316L is less likely to crack or distort during welding. The American Welding Society points out that welders really like it because it’s straightforward to work with and gives consistent results. That can mean saving time, cutting down on labor costs, and cutting back on rework.

Another tip: Make sure you’re using proper shielding gas coverage when welding with ER316L. Done right, this keeps your weld cleaner and boosts its resistance to corrosion overall.

Impact of ER316L on Weld Quality and Durability

So, ER316L is basically a low-carbon version of ER316, and it's really well-known for its awesome corrosion resistance and the fact that it makes welds look pretty clean and solid. When you’re working in industrial settings, using ER316L can seriously boost how long your welds last—especially in environments where chlorides and a bunch of chemicals are around. The secret sauce is its special alloy mix, including molybdenum, which gives it extra protection against stuff like pitting and crevice corrosion. That's why folks often choose it for things like food processing plants, chemical plants, or marine equipment.

And honestly, ER316L doesn’t just make your welds stronger; it also helps with the overall quality. Because it has low carbon content, it reduces the chances of carbide buildup during welding, which can cause corrosion over time. So, your welds stay in good shape longer, and you don't have to worry as much about failures or sudden maintenance costs. Plus, the weld beads it creates tend to be smooth and look pretty neat—adding a nice tidy finish, especially in situations where both performance and appearance really matter. All in all, it’s a go-to choice if you want reliable, good-looking welds in tough environments.

Tips for Choosing the Right ER316L for Your Welding Projects

When you’re choosing ER316L for your welding projects, it’s really important to get a good handle on what it’s used for and what benefits it offers. This is especially true if you’re working in industries that are dealing with stuff like labor shortages or just trying to get more done in less time. ER316L is pretty much the go-to because it resists rust and corrosion like a champ, plus it can handle high temps, so it’s perfect for things like chemical processing or food production. Knowing exactly what your project needs can make a big difference—helping you pick the right materials so your welds last longer and perform better.

Also, don’t forget to check the quality and type of ER316L wire you’re using. Look for certifications to make sure it meets industry standards—that’s always a good idea. And pay attention to the wire diameters because they can change how you weld and how strong your joints turn out. Getting these little details right means you can customize your approach to what your project demands, making sure everything runs smooth and that your results are solid. As industries keep evolving and new challenges pop up, making smart choices about materials like ER316L will really help you hit your goals and get the best outcomes.

Ultimate Guide to ER316L: Understanding Its Applications and Advantages in Industrial Welding

| Dimension | Value | Comments |

|---|---|---|

| Melting Point | 1370-1400°C | Suitable for high-temperature applications |

| Tensile Strength | 620 MPa | Exceptional strength for various welding requirements |

| Corrosion Resistance | Excellent | Ideal for marine and chemical environments |

| Common Applications | Chemical processing, Food and beverage industry | Widely used in industries requiring corrosion resistance |

| Welding Techniques | TIG, MIG | Versatile for different welding processes |

| Heat Treatment | Not recommended | Retains properties without heat treatment |

Elevate Your Welding Projects with AWS ER316L Stainless Steel Welding Wire: A Comprehensive Guide to MIG and TIG Techniques

Elevating your welding projects requires understanding the materials and techniques that can enhance your craftsmanship. One such material is the AWS ER316L stainless steel welding wire, renowned for its high cladding efficiency and impressive performance in all-position welding. This versatility makes it an ideal choice for various applications, ranging from building structures to bridge engineering, and even in sectors like mining machinery and railway construction. According to a report by the American Welding Society, the demand for stainless steel in industrial applications is expected to grow at a CAGR of 6.2% by 2025, highlighting the critical role materials like ER316L will play in future projects.

The technical performance of AWS ER316L is particularly noteworthy. This wire is designed for both MIG and TIG welding techniques, providing welders with the flexibility to choose their method based on the project's requirements. Its excellent corrosion resistance and strength at elevated temperatures make it suitable for gas pressure-bearing equipment and power machinery. With over 60% of stainless steel producers citing high demand for stainless products, utilizing a superior welding wire like ER316L can significantly improve the durability and longevity of your projects, ensuring they meet industry standards and expectations. Embrace these advancements to take your welding skills to the next level.

FAQS

: ER316L is a high-performance stainless steel known for its exceptional corrosion resistance and mechanical properties. It is especially useful in environments exposed to chlorides, making it suitable for applications in industries like chemical processing, marine construction, and pharmaceuticals.

Industries including chemical processing, marine construction, and pharmaceuticals benefit significantly from using ER316L due to its durability and reliability in challenging environments.

Utilizing ER316L in chlor-alkali equipment enhances longevity by providing strong resistance to corrosion and maintaining safety standards, which is crucial as this market grows.

When selecting ER316L for welding projects, it is important to consider the specific environmental conditions, employ proper welding techniques, and ensure compatibility with the intended application based on material specifications.

The low carbon content of ER316L minimizes the risk of carbide precipitation during welding, reducing the likelihood of intergranular corrosion and maintaining the integrity of welds over time.

ER316L enhances the durability of welds, particularly in corrosive environments, due to its unique alloy composition that includes molybdenum, which provides resistance to pitting and crevice corrosion.

Welds performed with ER316L exhibit smooth bead formation and an excellent aesthetic appearance, which is critical for high-stakes industrial applications where both performance and appearance matter.

The chlor-alkali equipment market is projected to reach $1.151 billion by 2032, underlining the importance of using robust materials like ER316L in this sector.

Proper welding techniques and training can significantly impact the quality of the weld and the performance of the finished product, helping to ensure optimal use of ER316L's properties.

ER316L is preferred for applications including food processing, chemical manufacturing, and marine equipment due to its excellent corrosion resistance and high weld quality.

Conclusion

Hey there! In our 'Ultimate Guide to ER316L,' we dive into what makes this welding wire special and why it’s a go-to choice in industrial welding. Basically, ER316L is a top-notch stainless steel alloy that’s praised for its fantastic resistance to rust and its durability — perfect for tough jobs like chemical processing machines or marine setups. One thing that really sets it apart from other stainless steels is its toughness and how well it resists pitting, which means your welds are stronger and tend to last longer — always a plus, right?

When you're picking out ER316L for your project, keep in mind a few key things like its low carbon content. That helps cut down the chances of carbide buildup, which can mess with the weld quality. And just so you know, with over 22 years of experience, Wenzhou Tianyu Electronic Co., Ltd. has got your back when it comes to top-quality welding electrodes and supplies. They’re committed to helping your projects perform better and stand up to the toughest environments out there.

Related Posts

-

Unlocking Potential with Best Hardfacing Welding in Mining 5 Key Applications Driving Efficiency

-

Challenges with Welding Quality Control in Global Supply Chains

-

Future Trends in Best Welding Rod Size for Global Buyers How to Navigate the 2025 Market Analysis

-

Emerging Trends in Stick Welding Stainless Steel for 2025 A Comprehensive Guide for Global Buyers

-

Exploring Innovative Techniques for Welding Cast Aluminum Alternatives

-

Exploring Innovations and Alternatives in Best Hard Surface Welding Rods for 2025 Global Market Trends

Blog Tags: