In industrial manufacturing, welding quality directly dictates product durability, safety, and operational costs. For buyers and plant managers navigating countless welding materials, solid wire stands out as a game-changer that consistently boosts weld integrity while aligning with modern production demands. This article breaks down how solid wire enhances welding quality and addresses the key industry-related questions you care about most.

A Brief Overview of Solid Wire for Industrial Welding

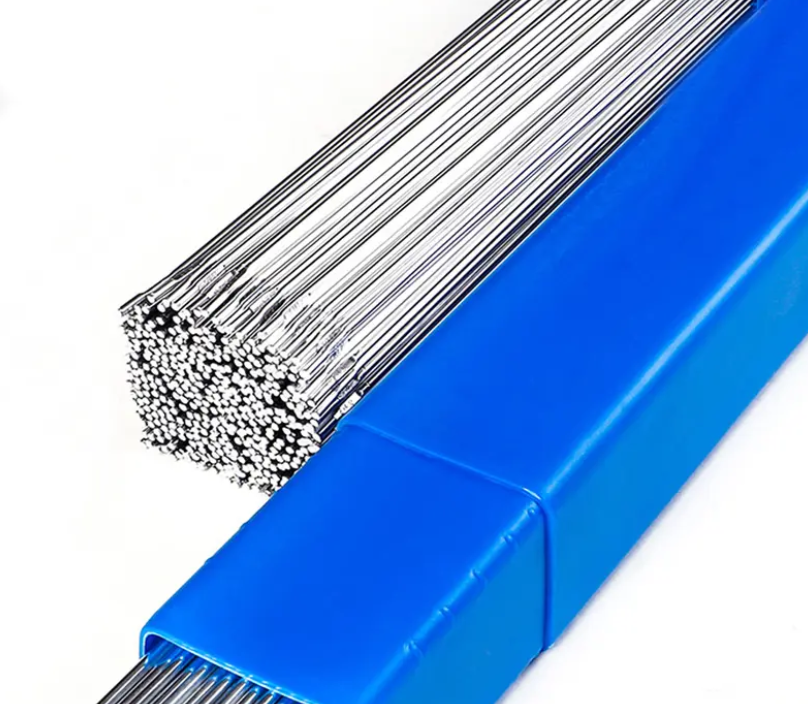

Solid wire refers to a homogeneous metal wire used as both a filler material and conductive electrode in welding processes like GMAW and MIG welding. Unlike flux-cored wire, it has a solid cross-section with uniform chemical composition, which lays the foundation for stable welding performance. While its production process is relatively straightforward compared to other welding wires, strict quality control over material purity and dimensional accuracy is required to meet industrial standards—an important consideration for buyers evaluating suppliers.

Core Advantages: How Solid Wire Boosts Welding Quality

1. Consistent Weld Formation & Reduced Defects

The homogeneous structure of solid wire ensures stable arc ignition and uniform droplet transfer during welding. This consistency minimizes common defects like porosity, cracks, and uneven weld beads—issues that plague many low-quality welding materials. For high-demand industries such as automotive manufacturing and heavy machinery production, this means fewer reworks, lower scrap rates, and welds that meet strict mechanical property requirements. For example, when welding 1000 MPa grade high-strength steel, properly selected solid wire can achieve tensile strength exceeding 1080 MPa and excellent low-temperature impact toughness.

2. Compatibility with Automated Production

Modern industrial manufacturing is increasingly shifting toward automation, and solid wire’s smooth surface and consistent diameter make it ideal for robotic welding systems. It enables stable wire feeding, reduces downtime caused by wire jams, and ensures consistent weld quality across high-volume production runs. For buyers investing in automated welding lines, this compatibility translates to higher production efficiency, lower labor costs, and predictable output quality—critical factors for scaling operations.

3. Cost-Effective Quality Enhancement

Compared to flux-cored wire, solid wire has a lower production cost and requires no pre-drying. When paired with affordable shielding gases like CO₂, it reduces overall welding costs by 40-50% compared to manual arc welding or submerged arc welding. For buyers balancing quality and budget, solid wire offers a cost-efficient solution that doesn’t compromise weld integrity—especially for medium to large-scale production projects.

Solid Wire & Industrial Welding Trends: What Buyers Need to Know

1. Industry-Specific Applications

Solid wire’s versatility makes it suitable for a wide range of industrial sectors. In automotive manufacturing, it’s used for welding body frames and components due to its high strength and consistent performance. In shipbuilding and construction, it excels in welding structural steel and pipelines, where weld durability is non-negotiable. It’s also widely adopted in aerospace and energy equipment manufacturing for precision welding of stainless steel and aluminum alloys. For buyers, understanding these application scenarios helps ensure the selected solid wire matches their specific production needs.

2. Green Production Alignment

Environmental regulations are tightening globally, and the welding industry is moving toward greener practices. Advanced solid wire products, such as copper-free solid wire, reduce smoke emissions and eliminate copper dust pollution during welding, creating a healthier workplace environment. For buyers operating in regions with strict environmental standards, choosing eco-friendly solid wire helps ensure compliance and enhances corporate sustainability credentials.

Practical Tips for Buyers: Selecting & Using Solid Wire

When selecting solid wire for your manufacturing needs, focus on three key factors: 1) Material compatibility—match the wire’s chemical composition to the base metal Welding process requirements—ensure the wire is suitable for your existing equipment Supplier reliability—prioritize suppliers with strict quality control processes to avoid batch-to-batch performance variations.

In use, maintain proper shielding gas flow to prevent weld contamination and adjust welding current and preheating temperature based on the base metal thickness. For example, welding 1000 MPa grade high-strength steel with solid wire achieves optimal results at 260 A current and 100 ℃ preheating temperature.

Conclusion: Solid Wire as a Cornerstone of High-Quality Industrial Welding

For industrial manufacturing buyers and managers, solid wire is more than just a welding material—it’s a strategic choice that enhances weld quality, improves production efficiency, and aligns with modern industry trends. Its consistent performance, compatibility with automation, and cost-effectiveness make it a reliable solution for meeting the rigorous demands of diverse industrial sectors. By understanding how solid wire elevates welding quality and selecting the right product for your specific needs, you can gain a competitive edge in production and product reliability.

Post time: Jan-13-2026