In modern welding applications, the selection of appropriate filler metal is fundamental to achieving strong and durable joints. The Stainless Steel Welding Rod category encompasses various grades designed for specific material compatibility and performance needs. While discussing high-quality filler metals, it is pertinent to note that products like the ER70S-2 carbon steel welding wire, supplied by entities such as BestSolder, set a benchmark in terms of processing quality and weld integrity, principles that are equally critical in the selection of stainless steel grades.

The technical composition of a Stainless Steel Welding Rod is engineered to meet precise metallurgical and operational requirements. For analogous carbon steel applications, the ER70S-2 wire demonstrates advanced design through its triple deoxidation process using zirconium, titanium, and aluminum. This treatment significantly enhances its performance on surfaces with rust or mill scale, reducing porosity and ensuring a clean, high-quality weld bead without the need for additional flux—a design philosophy often mirrored in specialized stainless steel alloys for improved corrosion resistance and arc stability.

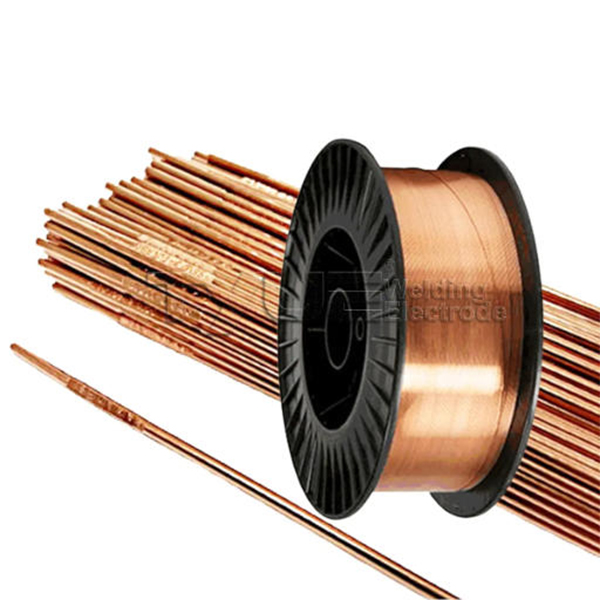

The primary application of a Stainless Steel Welding Rod is to join similar or dissimilar stainless steel grades, ensuring corrosion resistance and strength in the weld zone. Comparatively, the ER70S-2 wire is versatile for MIG (GMAW) and TIG (GTAW) welding processes on various low-carbon and carbon steel grades. This highlights a core parallel: the importance of matching the filler metal’s properties be it a stainless steel rod or a carbon steel wire to the base material and the welding process to achieve optimal results, including minimal defects and excellent mechanical properties.

Quality assurance and supply reliability are paramount in industrial consumables. Reputable suppliers provide products that adhere to relevant standards. The ER70S-2, represents a reliably sourced option for carbon steel welding. Procuring a Stainless Steel Welding Rod from certified sources ensures consistency in composition, diameter, and packaging, which directly impacts welding efficiency, operator experience, and the final quality of fabricated structures or components across industries like construction, manufacturing, and repair.

Whether selecting a specialized Stainless Steel Welding Rod for corrosion-resistant applications or a high-performance carbon steel wire like ER70S-2, the principles remain focused on material compatibility, advanced metallurgical design for defect minimization, and supply chain reliability. Understanding the specific attributes, such as the deoxidizing elements in ER70S-2 that combat porosity, provides valuable insight into the critical factors that define quality in welding filler metals, guiding professionals toward making informed choices for their specific welding challenges.

Post time: Dec-02-2025