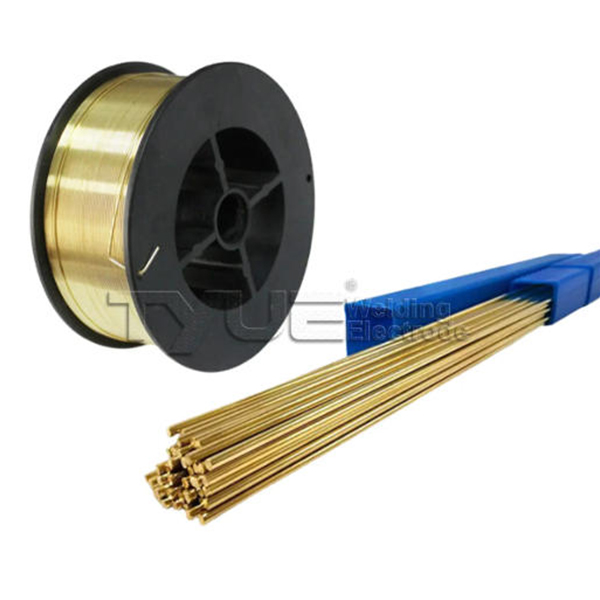

The Copper Alloy Welding Wire classified under AWS ERCu specification represents a specialized filler metal designed for high-quality joining processes. This deoxidized copper alloy wire is primarily formulated to create dense, sound weld deposits with relatively high electrical conductivity. As a specific type of Copper Alloy Welding Wire, it is suitable for use in inert gas shielded welding processes,TIG and MIG welding, making it essential joining and surfacing applications where copper’s characteristic properties are required.

The chemical composition of this Copper Alloy Welding Wire is engineered to provide optimal performance during the welding process. The deoxidizing elements within the alloy effectively prevent the formation of porosity in the weld metal, ensuring the resulting deposits are solid and reliable. This particular formulation of Copper Alloy Welding Wire typically falls under the category of brass welding wires, offering excellent bonding characteristics when joining copper alloys and facilitating repairs on various copper-based components.

This classification of Copper Alloy Welding Wire demonstrates specific physical properties that define its operational parameters. It possesses a solidus temperature of approximately 1020°C and a liquidus temperature of 1050°C, establishing its melting range for proper welding procedure development. With a density of 8.9 kg/dm³, this Copper Alloy Welding Wire handles predictably during automated and manual welding operations, providing consistent feedability and arc characteristics.

Welds produced using this copper alloy welding wire exhibit excellent mechanical properties, meeting stringent application requirements. The tensile strength of the weld metal is typically between 210-220 N/mm², with an elongation of 30% to 40%, indicating good ductility. The Brinell hardness is approximately 60 HB, confirming good compatibility between the weld and the base copper material, and providing sufficient strength for many industrial applications where copper components withstand operating stresses.

ERCu copper alloy welding wire combines excellent electrical conductivity, mechanical strength, and weldability. These properties make this type of copper alloy welding wire particularly important in fields such as electrical manufacturing, piping systems, and industrial maintenance, where reliable copper for copper connections is crucial. Its superior physical and mechanical properties ensure consistent welding results in a variety of welding applications across the manufacturing and repair industries.

Post time: Nov-11-2025