ER5183 is suitable for MIG welding the aluminium magnesium alloy that higher tensile strength is required and if the base metal is 5083 or 5654 the tensile strength would be much higher. It is widely used for welding aluminium magnesium alloy structures of ships, offshore platforms, locomotives & carriages, motor vehicles, containers, cryogenic vessels and so on. Its weld metal has good resistance to brine corrosion.

Welding Position: F, HF, V

Type of Current: DCEP

NOTICE:

Keeping the package of the wire in good condition before welding.

Both the surfaces to be welded of weldment and wire must be cleaned away impurities of oil contamination, oxide coating, moisture and so on.

To obtain good appearance of weld it is necessary to preheat the base metal to 100℃-200℃ before welding if its thickness is 10mm or more.

It is better to put a subplate under the weld zone to prop the melted metal so that to ensure complete penetration the weldment.

According to welding position and the thickness of base metal different shield gas should be chosen, such as 100%Ar, 75%Ar+25%He, 50%Ar+50%He, etc.

The welding conditions mentioned above for reference only and it is better to do a welding procedure qualification according to project before put it into formal welding.

ER5183 CHEMICAL COMPOSITION OF DEPOSITED METAL (%):

| SI | FE | CU | MN | MG | CR | ZN | TI | AI | BE | |

| Standard | ≤0.40 | ≤0.40 | ≤0.10 | 0.50-10 | 4.3-52 | 0.05-0.5 | ≤0.25 | ≤0.15 | Balance | ≤0.0003 |

| Typical | 0.08 | 0.12 | 0.006 | 0.65 | 4.75 | 0.130 | 0.005 | 0.080 | Balance | 0.0001 |

MECHANICAL PROPERTIES OF DEPOSITED METAL (AW):

| TENSILE STRENGTH RM (MPA) | YIELD STRENGTH REL (MPA) | ELONGATION A4 (%) | |

| Typical | 280 | 150 | 18 |

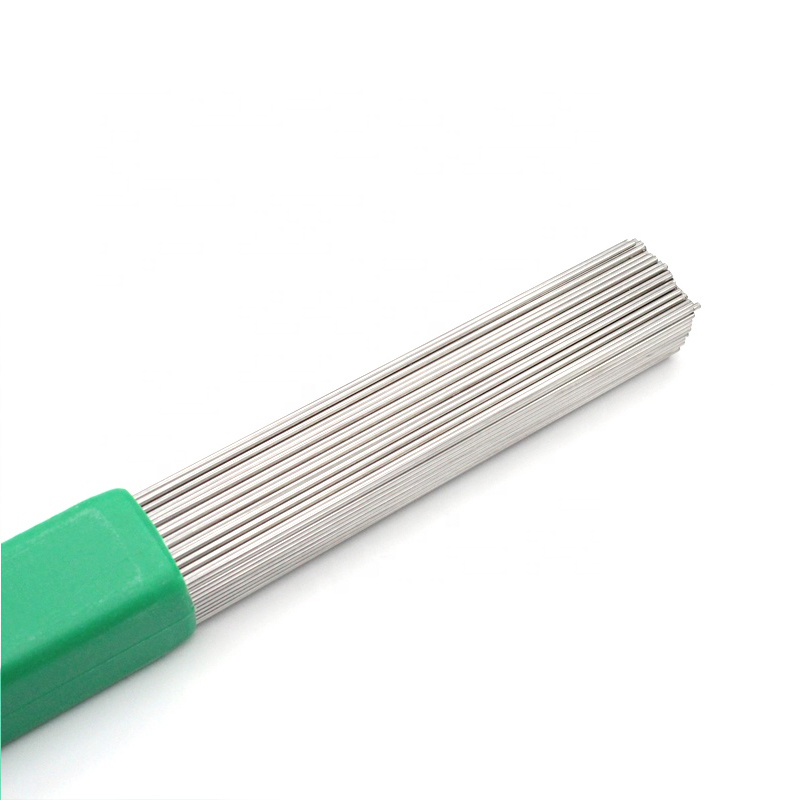

Sizes & Recommended Current for MIG (DC+):

| WELDING WIRE DIAMETER (MM) | 1.2 | 1.6 | 2.0 |

| Welding Current (A) | 180-300 | 200-400 | 240-450 |

| Welding Voltage (V) | 18-28 | 20-20 | 22-34 |

SIZES & RECOMMENDED CURRENT FOR TIG (DC¯):

| WELDING WIRE DIAMETER (MM) | 1.6-2.5 | 2.5-4.0 | 4.0-5.0 |

| Welding Current (A) | 150-250 | 200-320 | 220-400 |