rresponding Standard

-NB/T 47018.3-2017 S410NiMo

-GB/T 29713-2013 S410NiMo

-AWS A5.9M-2022 ER410NiMo

-ASME SFA-5.9M-2023 ER410NiMo

-YB/T 5092-2016 H05Cr12Ni4Mo

Equivalent Material: 1.4317 GX4CrNi13-4,1.4313 X3CrNiMo13-4,1.4407 GX5CrNiMo13-4,1.4414 GX4CrNiMo13-4,ACI Gr. CA6NM

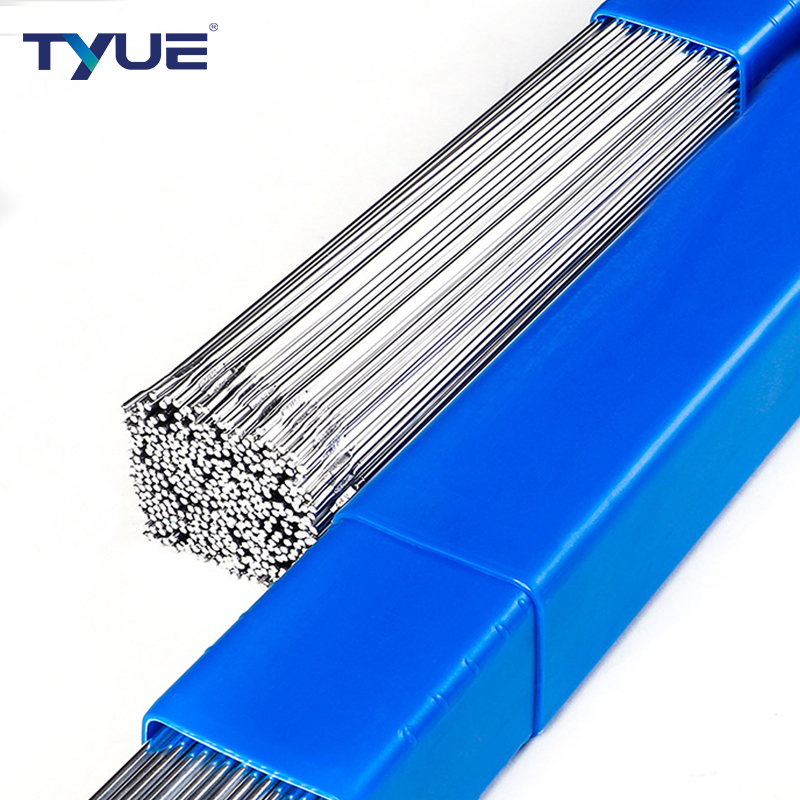

Description

ER410NiMo is a martensitic stainless steel solid wire with chemical composition featuring 11.0 – 12.5% Cr, 4.0 – 5.0% Ni, and 0.40 – 0.70% Mo. It is suitable for gas shielded welding (such as TIG/MIG) in all positions. During welding, the arc is stable, and the deposited metal exhibits excellent cavitation resistance, sand wear resistance,

and mechanical properties. Preheating is generally not required before welding; post-weld heat treatment (PWHT) at 580~620℃ for 2 hours (followed by air cooling,AC) is recommended as per application requirements. The deposited metal is machinable and suitable for pressure equipment.

Application

Designed for welding ASTM CA6NM cast steel, 410/410S/405 stainless steel, and similar 13%Cr – 4%Ni series steels. Typical applications include pressure equipment (conforming to pressure vessel standards), turbine blades, valves, high-pressure pipelines, and structural parts requiring corrosion and wear resistance.

Chemical Composition of Weld Metal (%)

| Element | C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| Requirement | ≤0.06 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | ≤1.00 | ≤0.60 | ≤0.050 | ≤0.020 | ≤0.75 |

| Test Result | 0.011 | 12.21 | 4.70 | 0.54 | 0.58 | 0.47 | 0.016 | 0.008 | 0.01 |

Mechanical Properties of Deposited Metal

| Test Name | Tensile Strength(MPa) | Elongation% | X-Ray | Impact Test(+20℃)J | Hardness HB |

| Requirement | ≥760 | ≥15 | Grade I | – | – |

| Test Result | 830 | 18 | Grade I | 65 | 250-310 |

Recommended Welding Parameter

Shielding Gas: Argon(Ar) or Ar+1-2% O2 (for TIG/MIG welding,adjust according to specific processes).

Notice

1.Ensure the wire surface is clean and free of oil, rust, or moisture before use to avoid affecting welding quality.

2.Maintain gas purity and proper flow rate to prevent porosity and hydrogen-induced cracking.