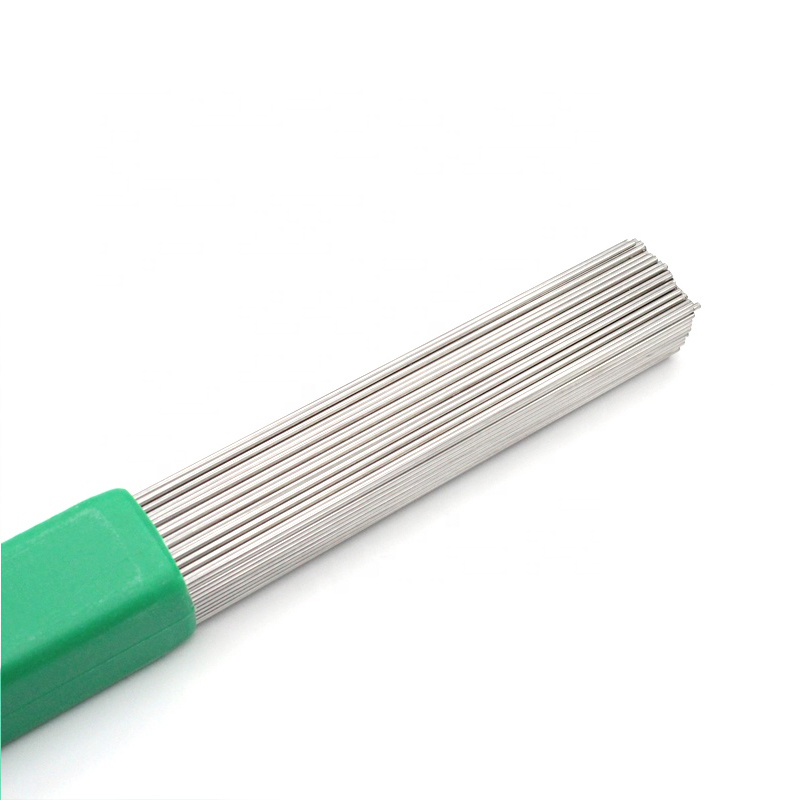

ER1100 A5.10, ALUMINUM AND ALUMINUM ALLOY Electrodes and Rods

ER1100 is highly resistant to chemical attack and weathering. It is a relatively soft alloy that is very formable and is used extensively in thin gauge and foil products. It has good wetting characteristics and it is also used as a filler alloy for welding purposes. A desirable characteristic of the alloy is the bright finishes obtained by anodizing.

Typical Applications: heat exchanges; food handling equipment; rivets; tie wire; metalizing

| AWS Class: ER1100 | Certification: AWS A5.10/ A5.10M:1999 |

| Alloy: ER1100 | AWS/ASME SFA A5.10 |

| Welding Position: F, V, OH, H |

Current: DCEP-GMAW AC-GTAW |

Typical Properties (as welded)

| Conductivity: | 59% IACS (-12) |

| Tensile Strength, kpsi: | 13 |

| Color: | Gray |

| Melting Point | 1215⁰F | Solidification | 1090⁰F | Density | 0.098 lbs/cu In. |

Typical Wire Chemistry as per AWS A5.10 (single values are maximum)

| Si + Fe | Cu | Mn | Zn | Other | Al | ||||||

| 0.95 | 0.05-0.20 | 0.05 | 0.10 | 0.15 | 99.0 min | ||||||

| Typical Welding Parameters | |||||||||||

| Diameter | Process | Volt | Amps | GAS | |||||||

| in | (mm) | ||||||||||

| .030 | (.8) | GMAW | 15-24 | 60-175 | Argon (cfh) | ||||||

| .035 | (.9) | GMAW | 15-27 | 70-185 | Argon (cfh) | ||||||

| 3/64” | (1.2 ) | GMAW | 20-29 | 125-260 | Argon (cfh) | ||||||

| 1/16” | (1.6) | GMAW | 24-30 | 170-300 | Argon (cfh) | ||||||

| 3/32” | (2.4) | GMAW | 26-31 | 275-400 | Argon (cfh) | ||||||

| Diameter | Process | Volt | Amps | GAS | |||||||

| in | (mm) | ||||||||||

| 1/16” | (1.6) | GTAW | 15 | 60-80 | Argon (cfh) | ||||||

| 3/32” | (2.4) | GTAW | 15 | 125-160 | Argon (cfh) | ||||||

| 1/8” | (3.2) | GTAW | 15 | 190-220 | Argon (cfh) | ||||||

| 5/32” | (4.0 ) | GTAW | 15 | 200-300 | Argon (cfh) | ||||||

| 3/16” | (4.8) | GTAW | 15-20 | 330-380 | Argon (cfh) | ||||||

Wenzhou Tianyu Electronic Co., Ltd. was established in 2000. We have been engaged in the manufacturing of welding electrodes, welding rods, and welding consumables for more than 20 years.

Our main products include stainless steel welding electrodes, carbon steel welding electrodes, low alloy welding electrodes, surfacing welding electrodes, nickel & cobalt alloy welding electrodes, mild steel & low alloy welding wires, stainless steel welding wires, gas-shielded flux cored wires, aluminum welding wires, submerged arc welding. wires, nickel & cobalt alloy welding wires, brass welding wires, TIG & MIG welding wires, tungsten electrodes, carbon gouging electrodes, and other welding accessories & consumables.