Stainless Welding Rods AWS A5.4 E309L-16

CHARACTERISTICS:

E309L-16 is an ultra-low carbon Cr23Ni13 stainless steel electrode used in rutile type pressure equipment. Cross – direct, can be used for all-position welding. The deposited metal has a low carbon content, so it can resist the inter crystalline corrosion caused by carbide precipitation when the stabilizer such as niobium and titanium is not contained.

APPLICATIONS:

It is suitable for welding the same type of stainless steel structure, composite steel and dissimilar steel components made by synthetic fiber, petrochemical equipment, etc. It can also be used for surfacing of transition layer of inner wall of pressure equipment of nuclear reactor and welding of structure inside tower.

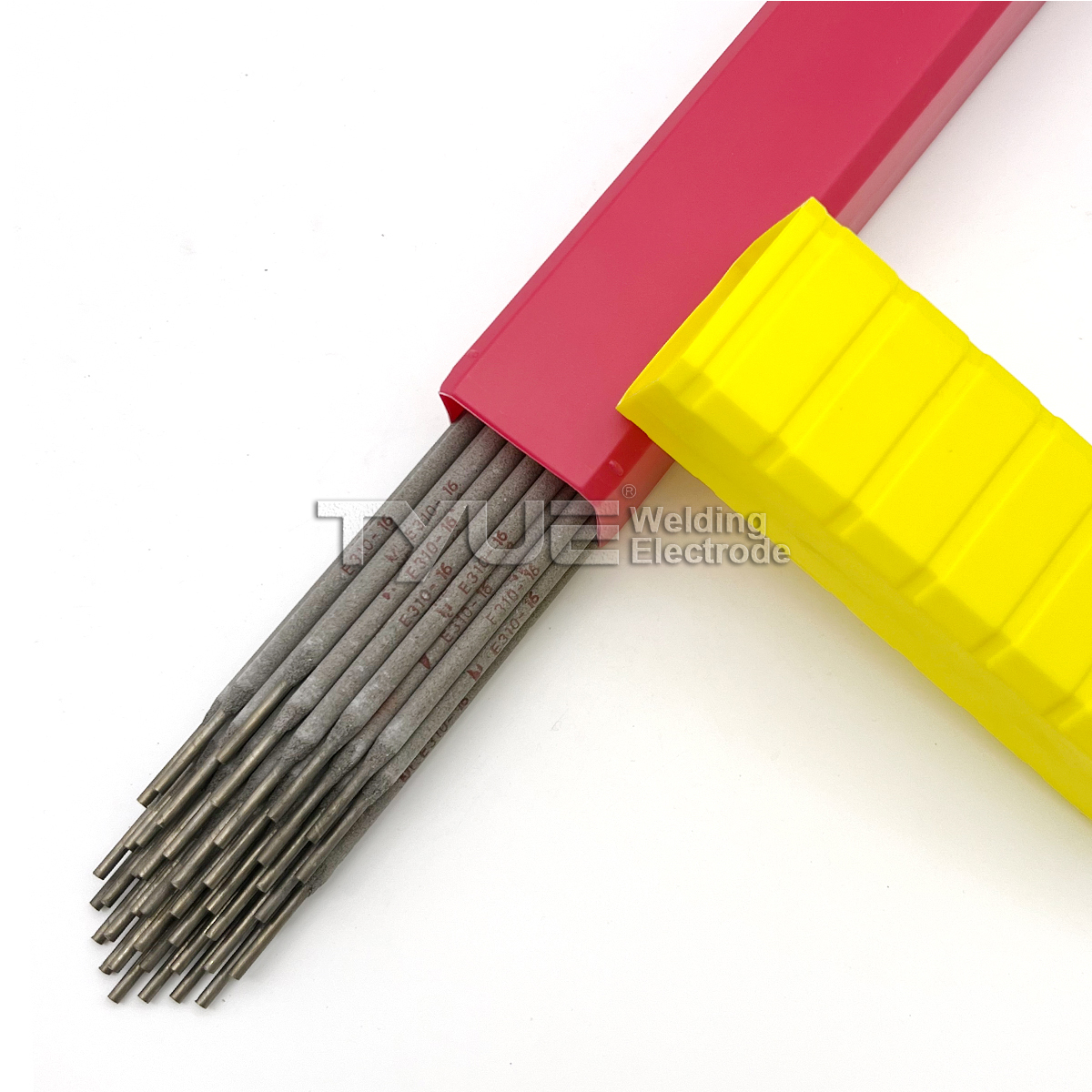

Product Description

| Model Number: AWS E309L-16 | Material: Stainless Steel |

| Length: 300mm-500mm | Operating Current: International standard |

| Welding Current: International standard | Operating Temperature: International standard |

| Diameter: 2.0mm,2.5mm,3.2mm,4.0mm | Application: synthetic fiber, petrochemical equipment,ect. |

| Color: grey-white |

CHEMICAL COMPOSITION OF ALL WELDING METAL: (WT. %)

| Items | C | Mn | Si | S | P | Cr | Ni | Mo | Cu |

| Requirements | ≤0.04 | 0.50~2.50 | ≤0.90 | ≤0.030 | ≤0.040 | 22.0~25.0 | 12.0-14.0 | ≤0.75 | ≤0.75 |

| Typical results | 0.035 | 1.05 | 0.67 | 0.012 | 0.031 | 22.9 | 12.58 | 0.032 | 0.030 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

| Items | Rm(MPa) | A/(%) |

| Requirements | ≥510 | ≥25 |

| Typical results | 560 | 42 |

TYPICAL OPERATING PROCEDURES: (AC OR DC+)

| Diameter (mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 |

| Current (A) | 40~80 | 50~100 | 70~130 | 100~160 | 140~200 |

ATTENTION:

1. Before welding, the electrode shall be baked at 320-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. Dc power supply is recommended, because the depth of current welding is relatively shallow, the current should not be too large, so as to avoid redness and cracking of the skin.

4. Reduce the heat input as much as possible, and the swing amplitude of the electrode should not be too large.

5. Preheat and keep the temperature between channels below 150℃.