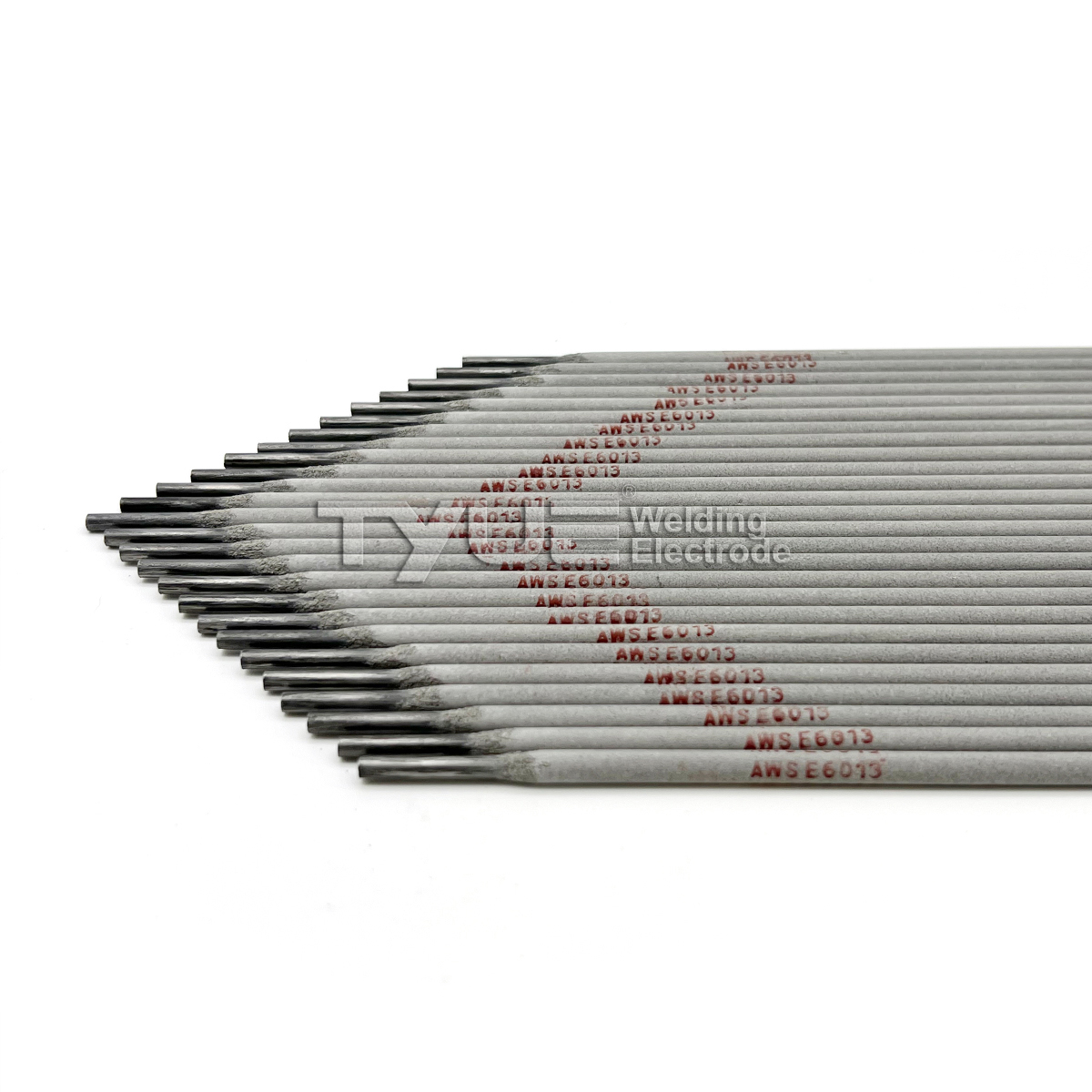

Welding rods AWS A5.1 E6013 (J421) is suitable for welding of low carbon steel structure, especially for the welding of thin plate steel with short discountinuous weld and requirement of smooth welding pass.

Classifications:

ISO 2560-A-E35 0 RA 12

AWS A5.1: E6013

GB/T 5117 E4313

Characteristics:

AWS A5.1 E6013 (J421) is a rutile type electrode. Can be welding both AC & DC power source and can be for all position. It have excellent welding performance as stable arc, little spatter, easy slag removal and reignition-ability etc. Rutile-cellulosic electrode with good weld ability in all positions including vertical down. Excellent gap-bridging and arc-striking ability. For tack welding and load fit ups. General purpose for industry and trade, assembly and shop welding.

Attention:

In generally, don’t need to re-dry the electrode before welding. When it be affected with damp, should be re-dry it at 150℃-170℃ for 0.5-1 hour.

Welding Position:

PA, PB, PC, PD, PE, PF

AWS A5.1 E6013 is suitable for welding structures made of low carbon steel, performs very well in welding thin and small size steel plates and also has very good performance in the situation that requires nice and clean bead appearance.

Chemical Composition of All Weld Metal: (%)

|

Chemical Composition |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Requirements |

≤0.10 |

0.32-0.55 |

≤0.30 |

≤0.030 |

≤0.035 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Typical Results |

0.08 |

0.37 |

0.18 |

0.020 |

0.025 |

0.030 |

0.035 |

0.005 |

0.004 |

Mechanical Properties of Deposited Metal

|

Test Item |

Rm (N/mm2) |

Rel (N/mm2) |

A (%) |

KV2(J) 0℃ |

|

Requirements |

440-560 |

≥355 |

≥22 |

≥47 |

|

Typical Results |

500 |

430 |

27 |

80 |

Reference Current (DC)

|

Diameter |

φ2.0 |

φ2.5 |

φ3.2 |

φ4.0 |

φ5.0 |

|

Amperage |

40 ~ 70 |

50 ~ 90 |

80 ~ 130 |

150 ~ 210 |

180 ~ 240 |

X-Ray Radiographic Inspection:

Level Ⅱ