DESCRIPTION:

Submerged Arc Cored Wires Low-Alloy Steel

CATEGORY:

AWS A5.23: ECM4 Submerged Arc Solid Wire is a low-alloy composite metal-cored wire electrode for submerged arc welding in high strength applications. AWS A5.23: ECM4 meets AWS A5.23 chemistry M4, and is designed for tensile strength levels above 110 ksi.

MAIN APPLICATION:

Single and multiple pass applications with the recommended submerged arc flux, High-Strength Low-Alloy steels, Quench & Tempered steels, Heavy equipment components, structural components, ship hulls, cast steels, boiler & pressure vessels

HSLA and Q&T steels

Structural fabrication

Jack-up rig fabrication

Heavy equipment frames

Crane beams

FEATURES:

Metal-cored wire can offer improved deposition rates compared to solid wires at comparable amperages

Metal-cored wires offer broader penetrationprofiles compared to solid wires at comparablewelding parameters

Very high strength deposit with excellent low- temperature toughness in the as-welded Condition

Weld deposit chemistry requirements are identical to those of EM4 solid wires

AWS CLASSIFICATIONS:

| With Flux | Condition | Specifications | Classification (US Customary Units) | Classification (SI Units) |

| SWX 150 | As-Welded | A5. 23/A5 23M | F11A10-ECM4-M4 | F76A7-ECM4-M4 |

| With Flux | %C | % Mn | %Si | %P | %S | % Cu | % Cr | % Ni | % Mo | %TI+V+Zr |

| SWX 150 | 0.06 | 1.45 | 0.27 | 0.012 | 0.010 | 0.06 | 0.31 | 2.25 | 0.47 | 0.02 |

TYPICAL WIRE CHEMICAL COMPOSITION:

| With Flux | Diffusible Hydrogen |

| SWX 150 | 7.5 ml/100g |

TYPICAL MECHANICAL PROPERTIES:

| With Flux | Condition | Tensile Strength | Yield Strength | Elongation % in 2" (50 mm) |

| SWX 150 | As-Welded | 113 ksi (779 MPa) | 106 ksi (731 MPa) | 20% |

| PWHT* | 104 ksi (717 MPa) | 97 ksi (669 MPa) | 8% |

TYPICAL CHARPY V-NOTCH IMPACT VALUES:

| With Flux | Condition | Avg. at -60°F (-50°C) | Avg. at -80°F (-60°C) | Avg. at -100°F (-70°C) |

| SWX 150 | As-Welded | 55 ft-lbs (75 J) | 60 f-bs (81 J) | 45 f-Ibs (61 J) |

| PWHT* | 57 f-lbs (77 J) | 45 ft-lbs (61 J) | — |

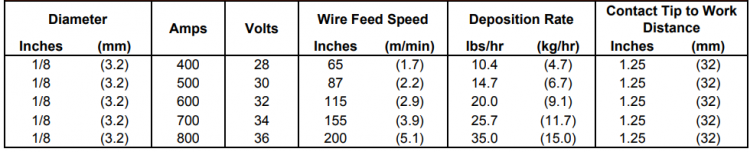

TYPICAL OPERATING PARAMETERS: