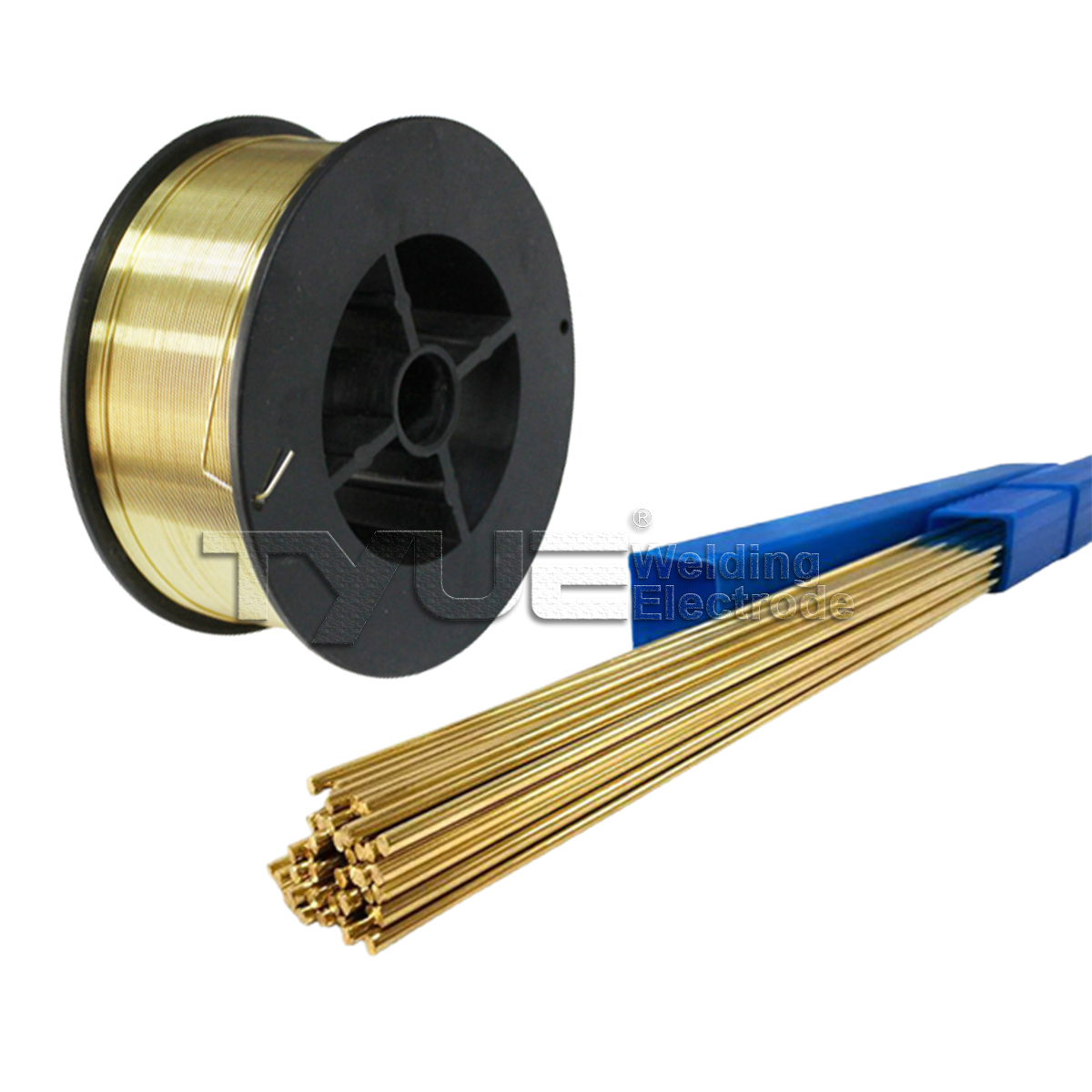

AWS A5.7 ERCuSn-C Phosphor Bronze wire

Introduction

Recommended for the welding of copper with Cu-Sn alloy. Best for the butt joining welding of brass with steel. Pre-heat suggested for the large size products, and pulsed argon arc welding is recommended for multilayer hard facing on steel.

| Standardization: | Numerical Symbol: | |

| GB/T9460-2008 | SCu5210 | |

| AWS A5.7:2007 | ERCuSn-C | |

| BS EN14640:2005 | Cu 5210 | |

| Composition(standard values): | % | |

| Cu incl.ag | bal. | |

| Zn | 0.20 | |

| Sn | 7.00-9.00 | |

| Fe | 0.10 | |

| P | 0.10-0.35 | |

| Al | 0.01 | |

| Pb | 0.02 | |

| Total others | 0.50 | |

| Physical properties of materials: | ||

| Density | Kg/m3 | 8.8 |

| Melting range | ℃ | 875-1025 |

| Thermal conductivity | W/m.K | 66 |

| Electrical conductivity | S.m/mm2 | 6-8 |

| Coefficient of thermal expansion | 10^-6/K(20-300℃) | 18.5 |

| Standard values of the weld metal: | ||

| Elongation | % | 20 |

| Tensile strength | N/mm2 | 260 |

| Notched bar impact work | J | 32 |

| Brinell hardness | HB 2.5/62.5 | 80 |

| Applications: | ||

| Copper tin alloy of higher tin percentage-increased hardness for overlay welding.Particularly suitable for welding of copper materials, like copper,tin bronzes,especially used for joining of copper zinc alloys and steels.Suitable for repair welding of cast bronzes and for oven soldering.For multilayer welding on steel,pulsed arc welding is recommended.For large work pieces preheating is recommended. | ||

| Make up: | ||

| Diameter:0.64 – 0.80 – 1.00 – 1.20 – 1.60 -2.40 | ||

| Spools:D100,D200,D300,D760,K300,KS300 | ||

| Rods:1.60 – 9.6 mm x 914/1000 mm | ||

| Electrodes available. | ||

| Further make ups on request. | ||

Wenzhou Tianyu Electronic Co., Ltd. was established in 2000. We have been engaged in the manufacturing of welding electrodes, welding rods, and welding consumables for more than 20 years.

Our main products include stainless steel welding electrodes, carbon steel welding electrodes, low alloy welding electrodes, surfacing welding electrodes, nickel & cobalt alloy welding electrodes, mild steel & low alloy welding wires, stainless steel welding wires, gas-shielded flux cored wires, aluminum welding wires, submerged arc welding. wires, nickel & cobalt alloy welding wires, brass welding wires, TIG & MIG welding wires, tungsten electrodes, carbon gouging electrodes, and other welding accessories & consumables.